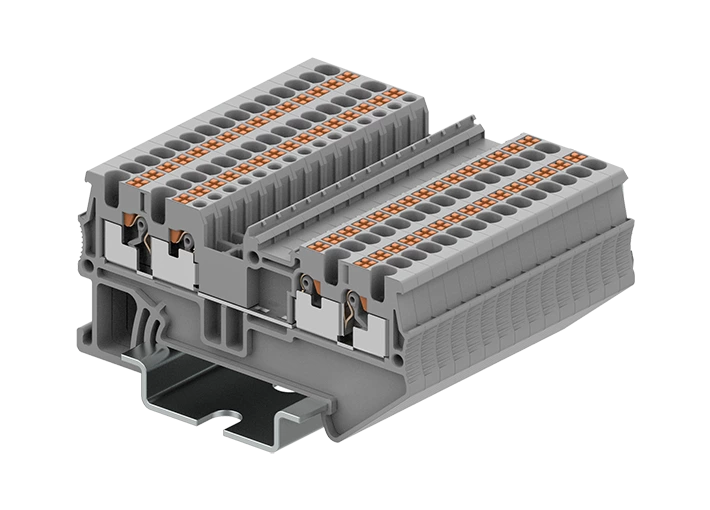

Push in spring terminal TP1.5-2-G

- Part:

- TP1.5-2-G

- Number of contacts:

- 2P

- Rated current:

- 17.5A

- Packaging Details:

- Standard Export Cartons

- Delivery Time:

- Within 7 Days

- Payment Terms:

- L/C, T/T, Western Union, Paypal

- Supply Ability:

- 100000 pcs per month

Push in spring terminal TP1.5-2-G

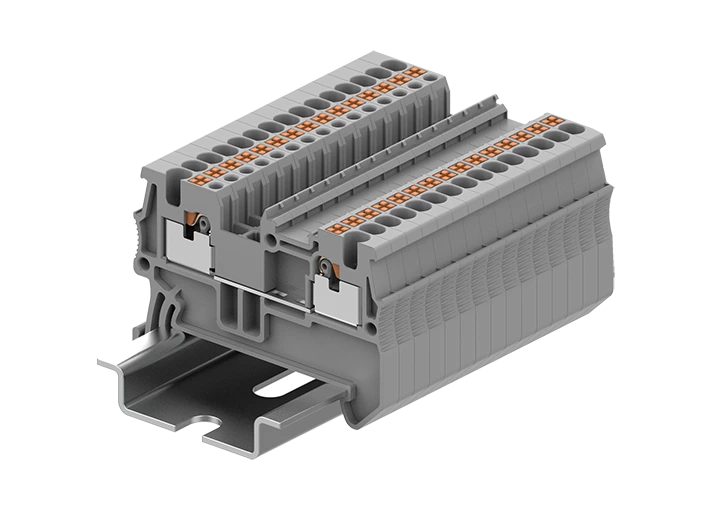

SMICO Push In Din Rail Mounted Terminal Blocks

1. DESCRIPTION:

The Push-in connection terminal blocks reduce the wiring time , and can support simply wiring in places where is only a little space available. You don't need any tool, just insert the cable is ok.

◆ Made from anti Inflaming Nylon PA 66, copper metal.

◆ Connecting, build bridges and labeling large or small conductor cross sections easily for feed through terminal blocks.

◆ Wiring can be handled in a limited space thanks to the compact design and front entry connection.

◆ With universal foot which can be installed on 35mm Standard Din Rail.

◆ Build electric potential distribution by using plug-in bridges in the terminal center.

◆ Available in all accessories: End covers, End Stoppers,Marker strips, Marker carrier, Plug-in bridge, etc.

Basic Information

|

SMICO ID |

TP1.5-2-G | ||

| Pitch | 3.5mm | ||

| Number of levels | 1 | ||

| Number of connections | 2P | ||

| Connection method | Push in spring terminal | ||

| Protection Level | IP20 | ||

| Work temperature | -40~+105℃ | ||

IEC Data

| Rated Current | 17.5A |

| Rated Voltage | 500V |

| Overvoltage category | Ⅲ |

| Pollution degree | 3 |

| Rated impulse voltage | 6KV |

| Conductor cross section solid | 0.2-1.5mm² |

| Conductor cross section flexible | 0.2-1.5mm² |

| Conductor cross section flexible,with furrule | 0.2-1.0mm² |

| Stripping length | 8-10mm |

UL Data

| Use group | B | C | D |

| Rated Current | 15A | 15A | - |

| Rated Voltage | 300V | 300V | - |

| Rated cross section | 26-14AWG | - | - |

Material Date

| Insulation material | PA66 |

| Insulation material group | Ⅲa |

| Flame retardant grade, UL94 compliance | V0 |

| Contact material | Copper alloy |

| Surface characteristics | Sn,Plated |

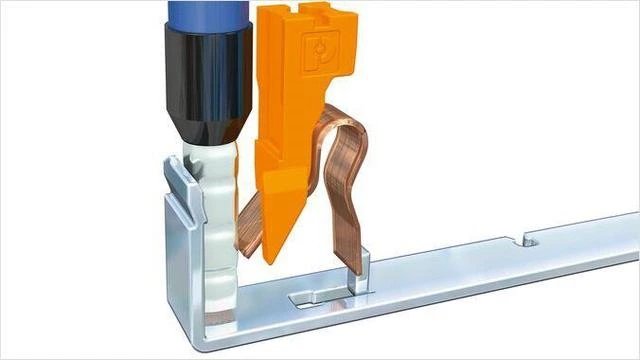

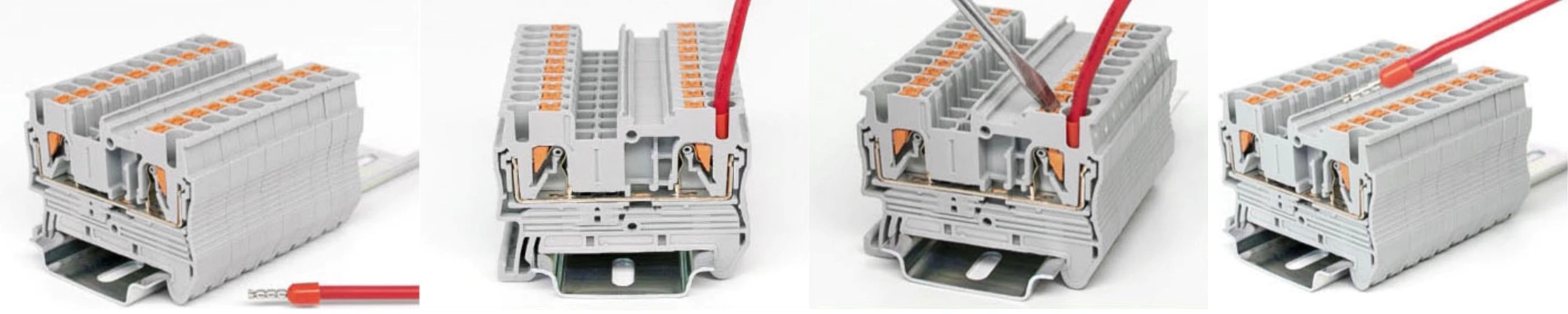

Set 1: Prepare the wires to be connected

Set 2: Directly insert the cable, no tools required

Set 3: Screwdriver into the orange button

Set 4: Unplug the wire, the wire withdrawal is complete

1: High-strength spring

2: Copper conductive strip

3: Imported flame-retardant nylon PA66

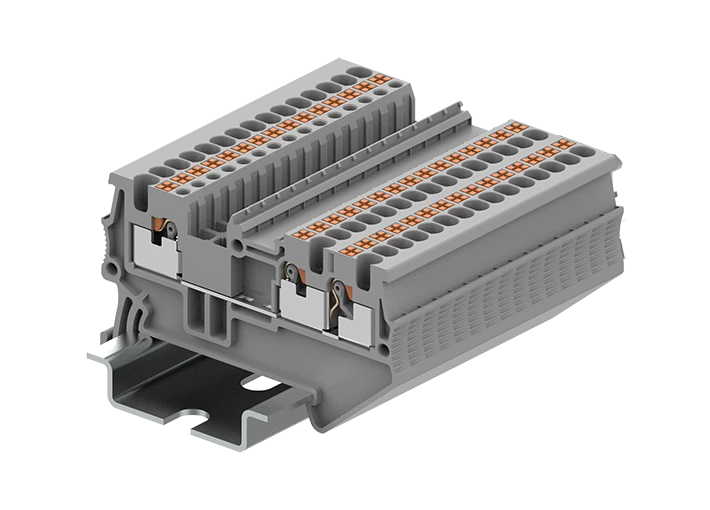

In-line terminal blocks, PT combined terminal blocks, high current terminal blocks

With the in-line connection technology, wires with a diameter of 0.25 mm? or more can be easily connected directly without tools. With contact springs, the wires can be inserted easily and the connection quality is high.

Advantage

With direct plug-in connection, the pre-treated rigid wire can be connected without tools, saving time

Easily insert wires, saving 50% of effort

The pull button is color-coded to ensure safe wiring and operation

No need to install tools, you can easily release the wire

Unified CLIPLINE complete system accessories to reduce logistics costs

Push-in terminal blocks are part of the COMPLETE line system

PT combined terminal block

The in-line connection PT series terminal blocks are suitable for connecting various wires with a nominal wire diameter of 1.5 mm to 185 mm.

Just insert a rigid wire with a wire diameter of 0.25 mm? or more or a flexible wire with a cold head into the wiring position, and the wiring is convenient and quick. The contact spring opens automatically, generating sufficient pressing force on the current bar. When installing a thin wire with a wire diameter of 0.14 mm? or more, use a standard screwdriver to unscrew the contact spring.

This series of terminal blocks takes full advantage of the CLIPLINE complete system. Various connection technologies and standardized system accessories can be freely combined.

PTV combines the advantages of in-line self-locking technology and screw terminal blocks

The PTV terminal block combines the advantages of tool-free in-line self-locking connection and side access of screw terminal blocks. The terminal adopts the tool-free direct insertion self-locking connection technology, the required wire insertion force is small, the connection is strong in vibration resistance, and the wiring time is saved. In addition, it also adopts the side entry design, the wiring position is clear, and there is no bending radius. Thereby, the vertical wiring between the wiring terminal and the line trough is realized, and it is easier to paste and read the cable identification.

Detailed explanation of in-line connection technology

You can directly connect rigid wires or prefabricated wires with ferrules without tools.

The special spring design can easily insert rigid wires with a wire diameter of 0.25 mm? or more and flexible wires with a cold press head to achieve a strong wire pull-out force.

Easily insert wires, saving 50% of effort.

By using the pull-out button, you can use various tools to loosen the wire without directly touching the live parts.

When connecting a flexible wire with a wire diameter of 0.14 mm or more without a ferrule, you only need to easily turn on the pull-out button when inserting it.

The pull button is color-coded to ensure safe wiring and operation.

Front wiring, easily connect various wires.