Technical Advantages Of Heavy-duty Connector Manufacturers

Heavy Duty Connector manufacturers usually have deep technical accumulation and a complete production system. In the design and manufacturing process, manufacturers need to propose customized solutions for specific application scenarios and produce according to industry standards and customer needs. These manufacturers usually improve the competitiveness of their products through the following technical advantages:

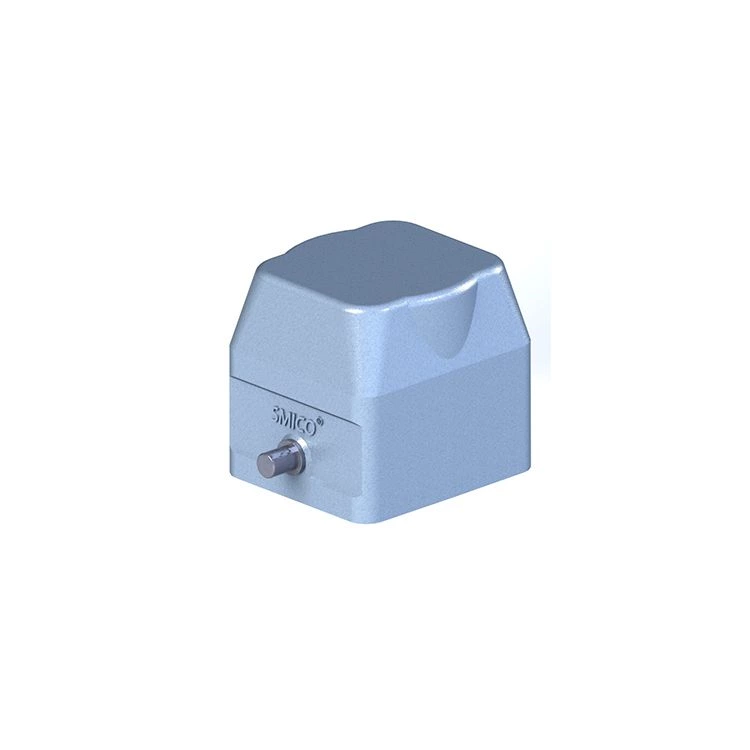

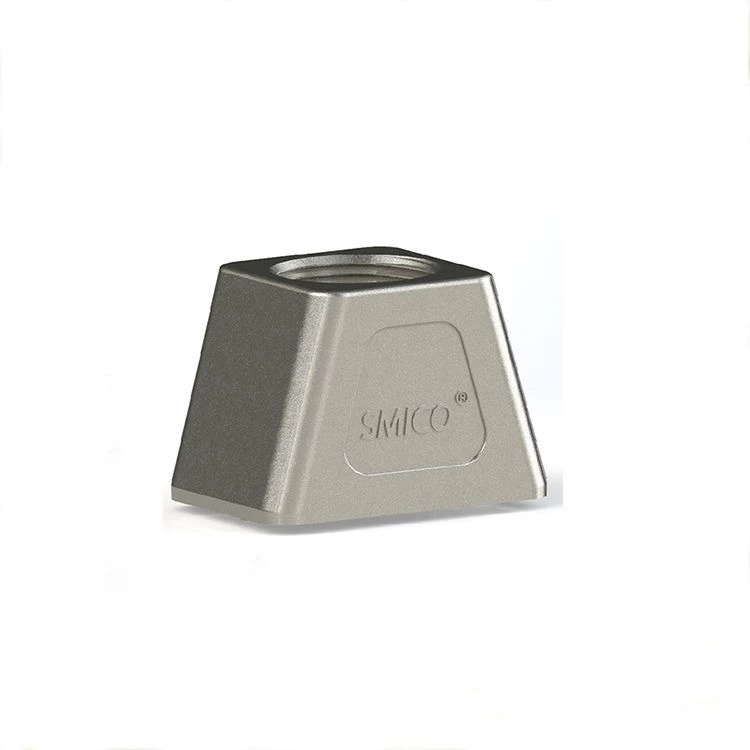

Selection of high-strength materials: In order to ensure that the connector can work stably under high load conditions, manufacturers often use high-strength, corrosion-resistant metal materials such as stainless steel, aluminum alloy, copper alloy, etc. At the same time, the insulating material also needs to have excellent high temperature resistance and electric shock resistance.

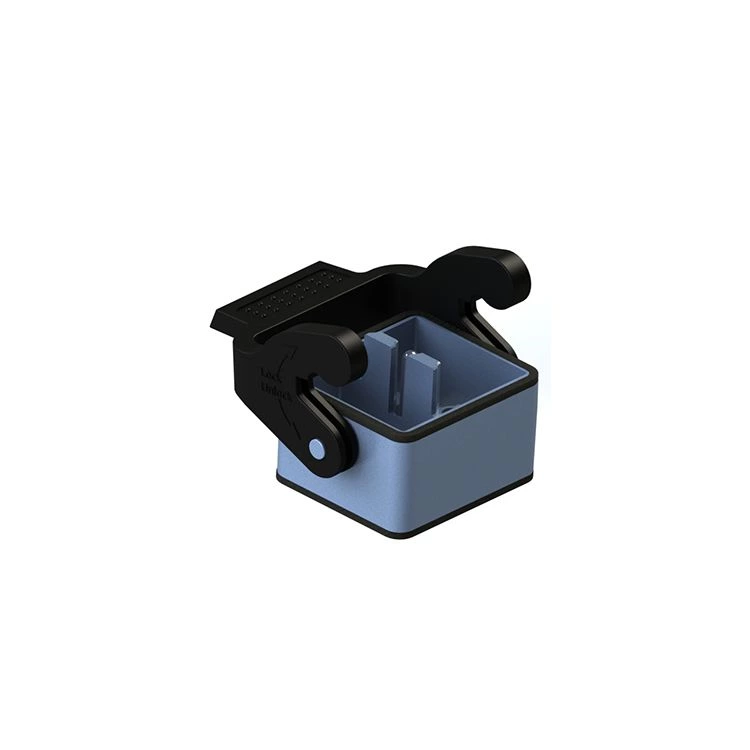

Protection design: Heavy-duty connectors are often used in harsh environments, so the manufacturer's products usually have IP67 and above waterproof and dustproof designs, which can effectively prevent dust, water vapor, etc. from affecting the internal circuit.

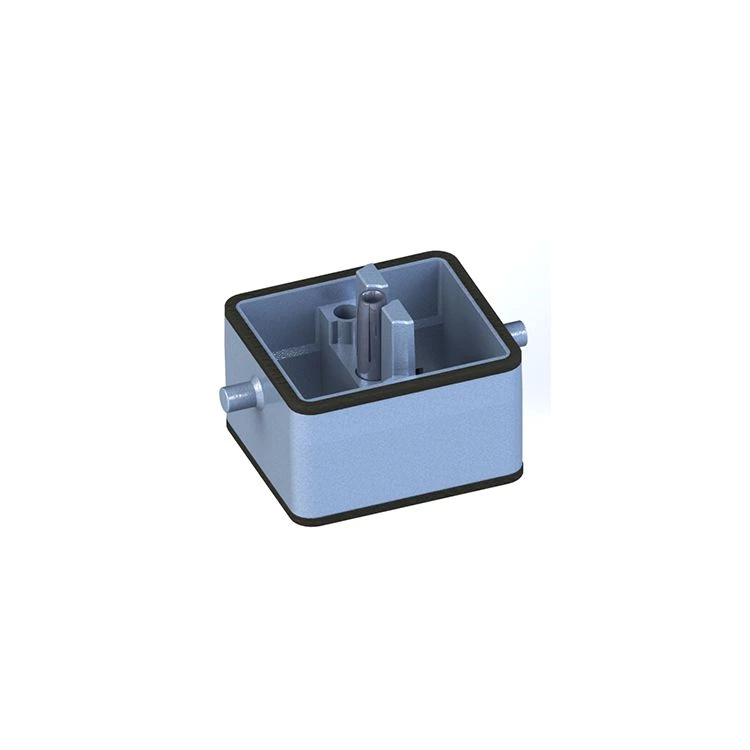

High current carrying capacity: Heavy-duty connectors need to be able to carry large currents and voltages, and the manufacturer's design must ensure stable electrical transmission, no overheating, and no poor contact. In addition, excellent contact design and metal coating technology are also key to ensuring high performance of connectors.