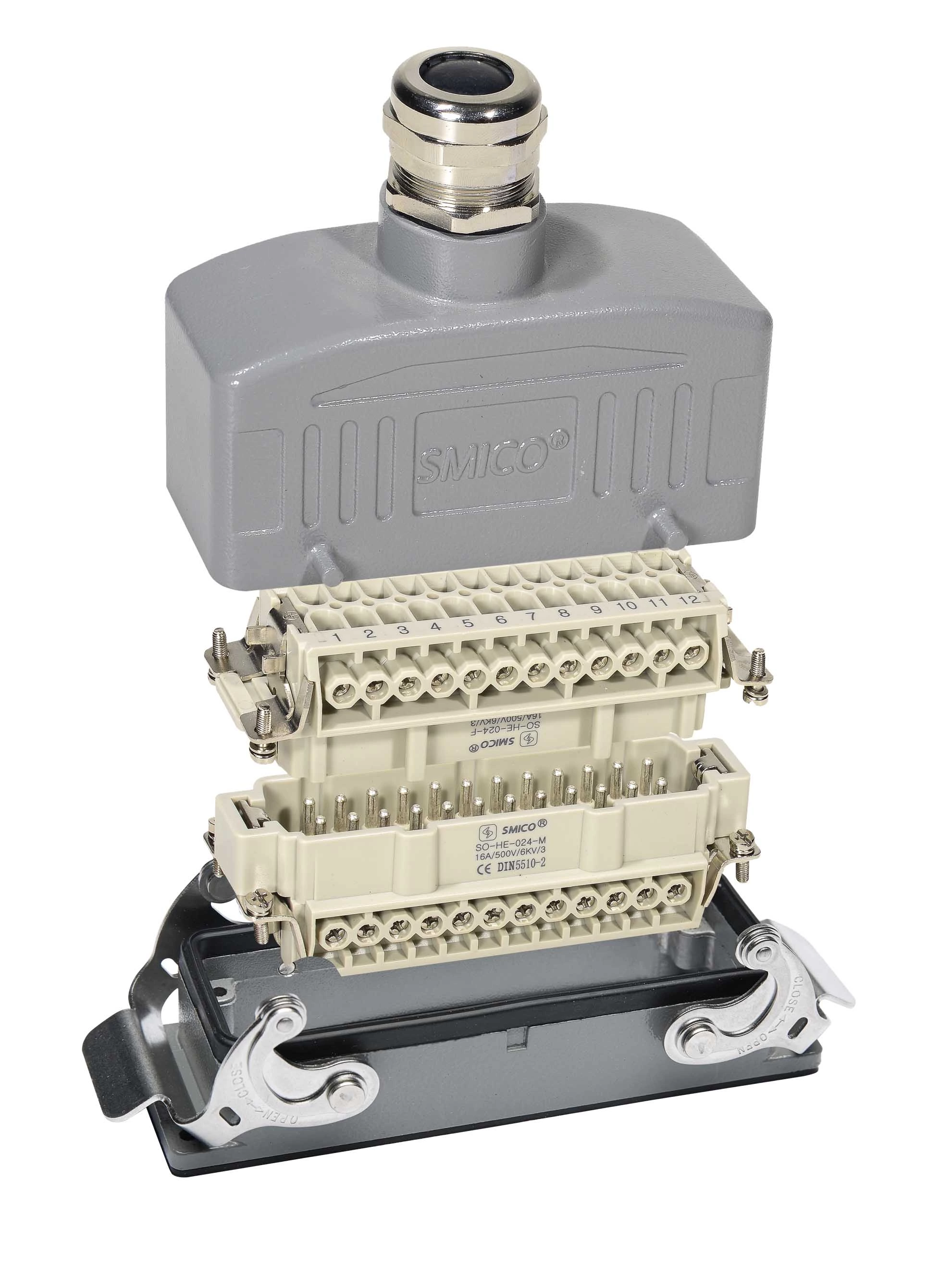

SMICO Push-In modules for fast and intuitive on-site assembly

New SMICO Push-In Module

At the moment when the concept of sustainable development has become a global consensus, in-line connection technology can help users better cope with demographic changes and the resulting shortage of skilled labor. Plug and play" assembly method.

When using ferrules or solid conductors, simply insert the stripped conductors from one side into the module's contact chamber and cage spring clips will secure the strands for tool-free assembly. Of course, users can also use a dedicated in-line tool for connection. The tool allows the push rod to be pushed in, holding the cage spring clips open, for easy, repeatable and safe insertion of the stranded wire into the contact chamber.

Save up to 30% on installation time

Push-in connection technology is an advanced version of the standard cage clamp for simple field connections. Ensuring fast and clean assembly of connectors while focusing on consistent quality and robustness. Various types of connectors in the SMICO Modular product portfolio can be applied to various wire cross-sections to meet the needs of different customers.

Different types of wires can be assembled with SMICO Push-In modules, including stranded wires without ferrules, wires with ferrules (insulated/non-insulated) and solid wires. Wider scope of application enables this termination technology to meet the needs of more market segments.

Tool-free connection makes operation easier

The in-line connection technology is especially suitable for on-site installation, and users can respond quickly and flexibly according to various needs and on-site environments. As the connection technique is tool-free, no additional assembly preparation steps are required. As a result, users are able to save a lot of working time and resources, further reducing costs.

In-line technology also facilitates easier access to components in tight operating space environments during maintenance operations, requiring only enough room to pull out and reinsert the tubular tip. Therefore, this technology is particularly suitable for occasions that require high flexibility, such as changing parts on the machine.