Small Size Plays A Big Role. How To Choose The Right Industrial Connector

In recent years, with the continuous improvement of the level of industrial automation, connectors not only simply guarantee the interoperability of equipment, but also expand their functions to the connection between equipment and the reliable protection of current and signal transmission. Therefore, more and more users hope that connectors can be used in various environments and connect various equipment and systems.

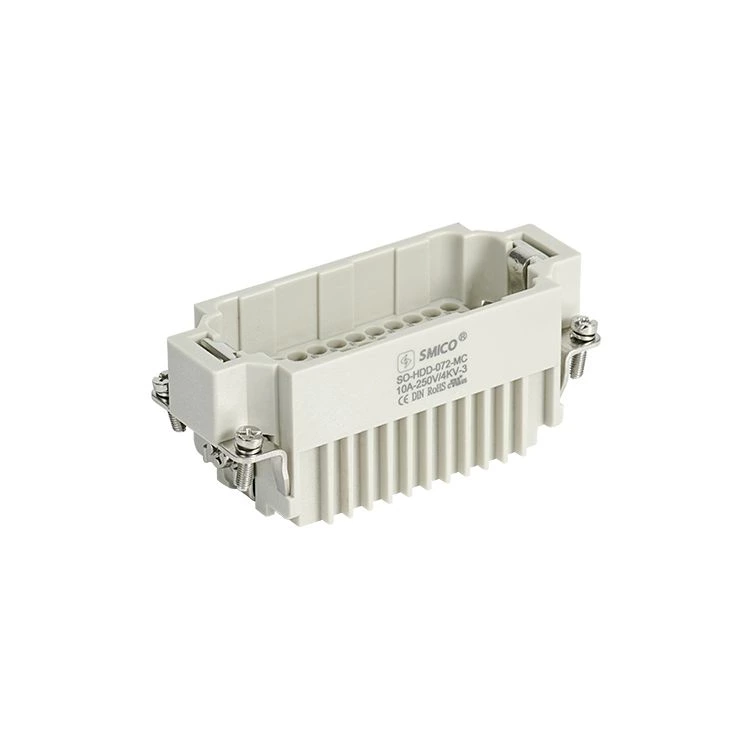

1.Heavy Duty Connector There are many types and can be applied to various fields of industrial automation. How to choose the right industrial connector? ! What do you need to connect? Where is it used? First of all, this determines the type of industrial connector selected. The connector has a variety of structures and a wide range of uses. Users need to understand their needs before making a choice.

1. Next, let's look at the application of connectors in real life.

1. In rail transit, such as on EMUs or high-speed trains, how can we talk more smoothly, browse the Internet more smoothly, or watch high-definition videos? You must know how important it is to view intermittent signals on the train, and the connector is responsible for the stable transmission of signals so that you can enjoy smoother WiFi.

2. Industrial connectors play a unique role in power plants, especially outdoor switchgear. Often exposed to sunlight, wind, dust, rain, and ice, they provide safe connections for control cabinets.

3. Reliable and proven connectors are particularly popular in the wind energy field, such as the fan's mud replacement system.

4. Connectors are also indispensable for robots. Due to the presence of connectors, robots become easier to operate and automate.

5. In the production process, such as CNC-controlled 3-5-axis machining centers, boring, milling machines, drilling machines, etc., multi-axis linkage CNC systems cannot be separated from the connector, and USB, TCP/IP networks are opened for DNC processing and data transmission.

6. In fact, lathes, plastic processing machinery, printing presses, metal processing and wood processing machinery, electric cranes, semiconductor production equipment, food and beverage processing and packaging machinery will be used to connect power, signals and data.

7. This is a Siemens distributed drive product. The drive on the left and the motor on the right are connected by an orange cable with a Haoting connector at both ends of the cable. It can be imagined that if the connector is not used and a fixed cable is used, the distance between the left and right devices is not only fixed, but also very inconvenient if the two devices need to be moved or transported together. With the connector connection, the two devices can be packaged and transported separately and can be disassembled at any time, which is very convenient.

8. Therefore, the connector is everywhere in our lives, dotted with its shadow, either clear or blurred. The most obvious manifestation is the mechanical connector. Instruments with interfaces at both ends play a connecting role.

9. The advantages of the connector have expanded it in the field of life and show different roles. The convenience of our lives cannot be underestimated. What are the advantages of the connector?

10. The bridging function of the connector and its convenience. The connecting function of the connector changes the shortcomings of the overall space gap, connects the combination of large spaces, thereby realizing the connection between three-dimensional planes and realizing the unification of planes. This is the advantage of the connector, simple and practical. Female patients.

11. Secondly, the connector is simple and concise. Once the connection problem is found, it is easy to repair and replace, and the connector upgrade speed is fast, which can realize the transformation and replacement of internal components, which is more important for the cost saving and safety guarantee of the entire project. Third, it is easy to maintain and quickly upgrade.

12. The flexible design of the connector is also one of the main criteria for our selection. The connector is compact in design, easy to install and disassemble, ensuring its safety and integrity. This deeply reflects the classic theory that condensation is the essence.

13. Therefore, as an electromechanical component, the connector plays a huge role in our lives. It provides a bridge to connect systems, subsystems or components, and transmits signals or energy. It is an indispensable product for electrical and electronic products. It realizes the combination of this shore and the other shore. It is like a bridge that supports a smooth and unobstructed road surface. .Since the connector is so important, how do we choose the connector we like in practical applications?

14. In fact, the quality of the connector actually depends mainly on the main purpose of the connector and the performance that needs to be met, because each connector has its own *** in design and development, which is called "the best for itself". So, if you want to choose a good connector, you can refer to the following aspects to consider.

15. What is a connector? Where is it used? These questions are questions that need to be considered, which determines the type of industrial connector selected.

16. Due to the wide variety of connectors, each company has a variety of connectors, so users need to have a deep understanding of their needs before they can choose a connector that meets their needs.

17. After selecting the type of connector, the environmental requirements, electrical requirements and mechanical properties of the connector must be determined. When choosing the type of connector to use, there are many connectors of the same type that can meet different performances.

18. The third step of selection is also a key step, because the user already knows what kind of connector he needs and needs to decide who to buy.

19. Choosing a guaranteed industrial connector must consider its safety certification. At present, there are many connector manufacturers. However, due to the different materials and production processes produced by different manufacturers, not all connector manufacturers can pass the international general safety certification, so connectors with international certification are also selected. Choose a guaranteed connection and choose a brand that has been tested for many years.

20. The industrial manufacturing industry is moving towards automation and intelligence. Industrial connectors have been widely used in all aspects of industrial production to realize industrial interconnection. Therefore, it is very important to choose high-quality connectors.