Selection Principles Of Industrial Connectors And Detailed Description Of Common Connection Methods

In recent years, with the continuous improvement of industrial automation, connectors not only simply guarantee the interoperability of equipment, but also expand their functions to the connection between equipment and the reliable protection of current and signal transmission. Therefore, more and more users expect connectors to be used in various environments and connect various devices and systems.

Connector manufacturers can use about 25 test agencies (specifications) as the source of all or part of their connector test specifications. It is necessary to consider the use of appropriate test specifications in specific application situations, including internationally common test specifications.

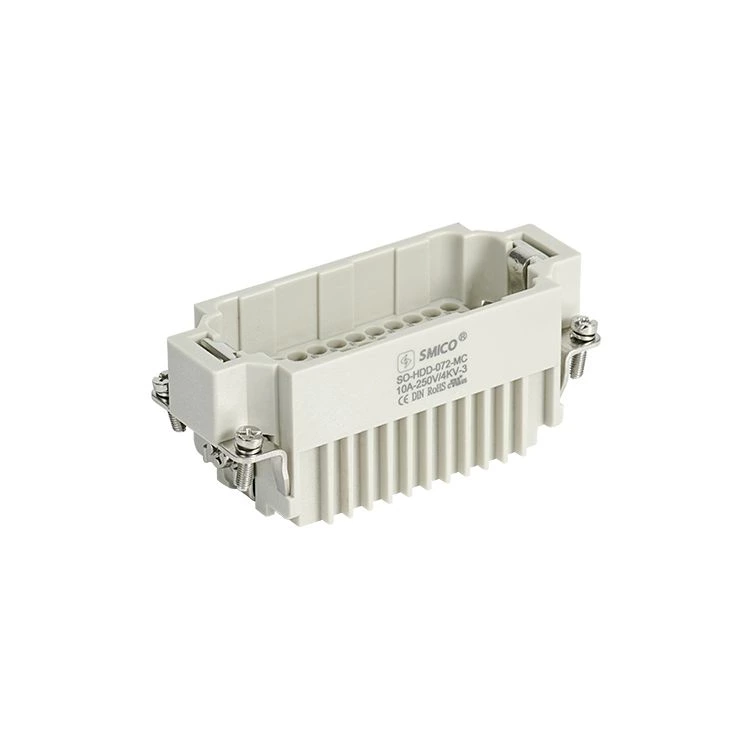

When selecting Heavy Duty Connector, the electrical requirements of the product should be considered. What are the voltage and current requirements of the product, and whether the connector can be well applied to such electrical performance, these questions about electrical requirements need to be considered. In addition, we also need to consider other electrical conditions: resistance, allowable resistance change, millivolt drop, maximum current, maximum voltage, inrush current, characteristic impedance (VSWR), plug and plug loss shielding efficiency.

Environmental conditions such as temperature and humidity are determined by the location of the electrical connector, so the location and expected environment should be considered. What is the applicable period of other relevant storage conditions and information? The environmental description should also include requirements for shock and vibration, including shock and vibration generated by sea transportation, and production conditions such as welding temperature and welding cycle duration. Connector manufacturers say that the area around the converging continuous current guided by the connector is the area where the highest temperature is generated.

For connectors, what volume and footprint are effective; what is the allowable dimensional tolerance; what is the insertion force and extraction force of the terminal; what is the durability of the connector (the frequency of plug and unplug mating)? These factors should be considered when selecting electrical connectors. For example, for printed circuit boards, it is very important to determine the tolerance of the printed circuit board. It is the critical value of edge connectors and the feasibility of achieving critical values. For low-power circuits, plating and underlying materials must be specified according to signal standards and environmental levels.

A new industrial connector is designed to establish a strong Ethernet connection in harsh environments. It is more rugged, stronger and more resistant than previous connectors. This new interface is widely regarded as an "industrial connector" and its application is not limited to manufacturing. This connector is designed to withstand the harshest industrial conditions.

1. Threaded connection is a traditional connection method that is relatively rare at present. It is useful to work in some large-sized components or strong vibration environments. The advantage of this connection form is strong reliability, and the cable is fixed by the friction of the nut gear. If combined with a fuse to prevent loosening, the effect will be better. The disadvantage is that the disassembly speed is relatively slow, and it takes a little electricity to retract the thread, which is time-consuming.

2. Sliding connection is a commonly used form of quick connection and separation. It is usually used to connect two simple electrical components. The connector connected by the clip type will mark the correct locking direction of the clip at the clip. The user can observe whether the clip is installed through the small hole on the side of the connector nut.

3. Plug-in connection is a common connection method. Horizontal movement can realize the connection and separation of plugs and sockets. It does not require twisting and installation, and only takes a short time to complete the connection and separation. There are two structures of ordinary plug-in connection: ball type and pin type. This connection eliminates the traditional mechanical locking mechanism, so once the connector is inserted incorrectly, it is difficult to pull it out.

4. The cabinet connection adopts an electrical connection method, which needs to be blindly connected with the equipment near the rack. Using this method, the electrical equipment can become very light and can work independently between units. It is easy to maintain and has high reliability. Since the operator cannot perceive the connection in this connection mode, there must be a precise positioning device to help the connection go smoothly. Floating contact or spring design is usually used to ensure correct connection.

5. Soldering connection refers to the formation of continuous metal between the solder and the welding surface. Therefore, the prerequisite for the connector is solderability. Common coatings on the connector welding end are tin alloy, silver and gold. The reed contact with the ordinary welding end has pad type, stamping pad type and notch pad type: the pinhole contact with the ordinary welding end has a drill arc notch

6. Perforated connection, also known as insulation displacement connection, has the characteristics of high reliability, low cost and easy use, and has been widely used in the printing industry. It is suitable for the interconnection of ribbon cables. There is no need to destroy the insulation layer of the cable when connecting. With the help of the connector U-shaped contact spring, the conductor of the cable slides into the groove of the connector and is fixed, so that the cable and the connector are in close contact.