Rectangular Connector Manufacturers: The Key Force Connecting Technology And Industry

Heavy Duty Connector is an indispensable component of modern electronic and electrical equipment, and is widely used in computers, communications, automobiles, industrial equipment and other fields. With the advancement of technology and the increase in industrial demand, the demand for rectangular connectors continues to grow, and the role of rectangular connector manufacturers has become increasingly important. These manufacturers must not only meet technical requirements, but also adapt to market changes and customer needs to provide high-quality products and services.

Definition and application of rectangular connectors

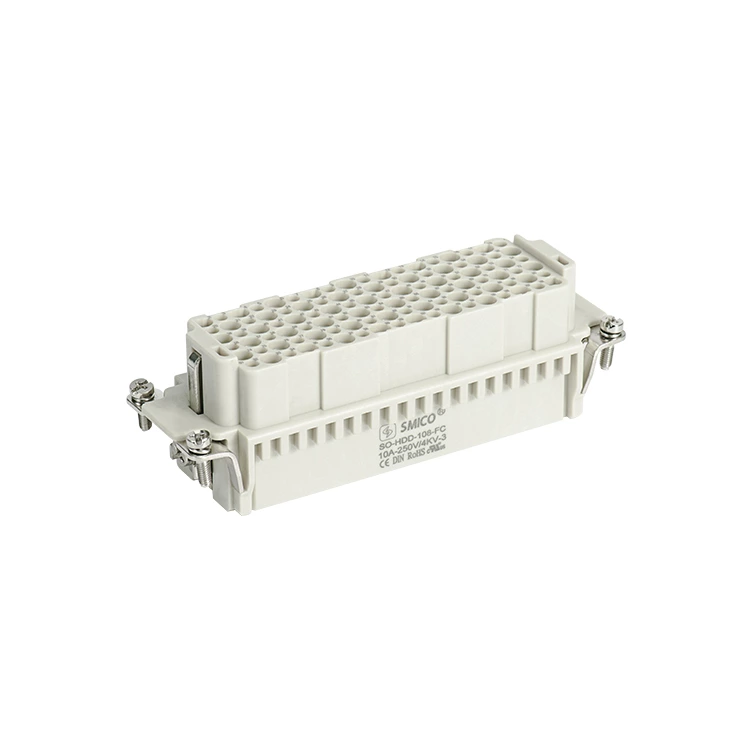

Rectangular connectors, as the name suggests, are connectors with a rectangular shape. Compared with connectors of other shapes, rectangular connectors generally provide more pin configurations and higher durability. The design of this connector allows the parallel transmission of multiple electrical signals and is widely used in occasions that require high-density connections and stability. Typical applications include computer motherboards, communication equipment, automotive electrical systems, and industrial control equipment.

Role and challenges of rectangular connector manufacturers

As a manufacturer of rectangular connectors, manufacturers need to have certain technical capabilities and market insights. First of all, manufacturers must have advanced manufacturing equipment and technology to ensure the quality and performance of connectors. Every link in the production process, including mold design, material selection, manufacturing process and quality control, has an important impact on the reliability of the final product. Secondly, manufacturers also need to pay attention to changes in market demand and personalized requirements of customers, and provide customized solutions.

In terms of challenges, rectangular connector manufacturers need to deal with pressure from multiple aspects. The first is the challenge of technological progress. With the complexity of electronic equipment and the improvement of performance requirements, the design of connectors also needs to be constantly updated. Manufacturers need to invest a lot of resources in research and development to maintain technological leadership. Secondly, the market competition is fierce, especially in the context of globalization, manufacturers need to compete with other competitors in terms of price, quality and service. Price pressure and supply chain management are also issues that manufacturers must face.

Market status and prospects of rectangular connector manufacturers

At present, the rectangular connector market shows a trend of diversification and globalization. Many manufacturers not only have a place in the local market, but also actively expand the international market. This trend of globalization not only brings greater market opportunities, but also makes manufacturers face a more complex competitive environment. In order to adapt to market changes, manufacturers need to flexibly adjust production strategies, strengthen communication with customers, and respond quickly to market demand.