Quickly understand several connection methods of heavy duty connectors

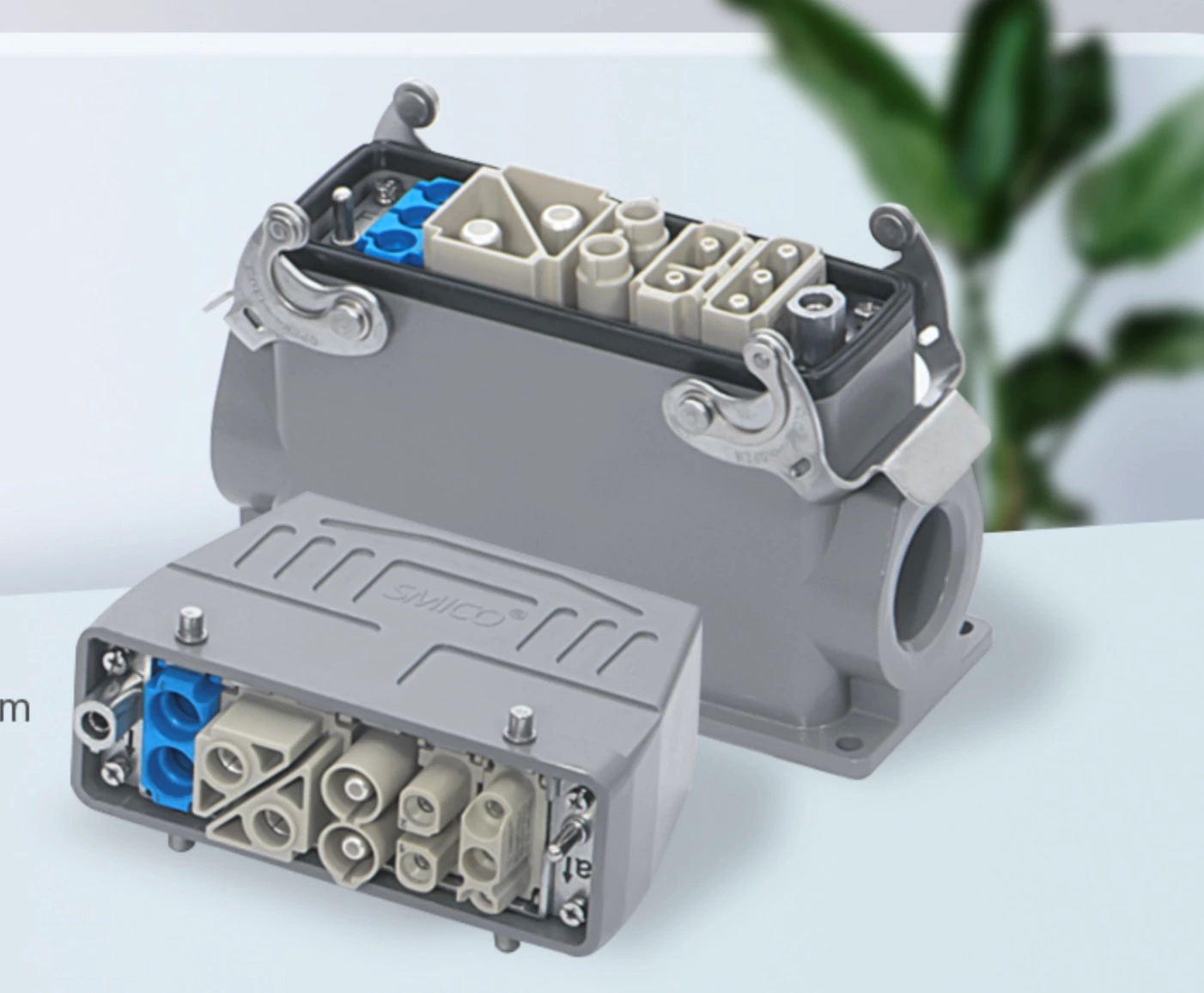

Definition of heavy-duty connectors: also known as HDC heavy-duty connectors, aviation plugs, industrial plugs and sockets. There are many types of overloaded connectors, but the connection methods are nothing more than these.

With the continuous development and upgrading of the domestic equipment manufacturing field, heavy-duty connectors are also increasingly widely used. The editor also sorted out several connection methods of overloaded connectors and shared them with you.

Definition of heavy-duty connectors: also known as HDC heavy-duty connectors, aviation plugs, industrial plugs and sockets.

Heavy-duty connectors are widely used in many industrial fields. Regarding the application fields and application cases of heavy-duty connectors, you are welcome to view other information and videos on this site.

The inner core of the heavy-duty connector mainly adopts the following connection methods:

1. Screw connection

2. Cold press connection

3. Shrapnel connection method

4. Bolt connection

The following will share the characteristics of various connection methods and the corresponding connector core series one by one.

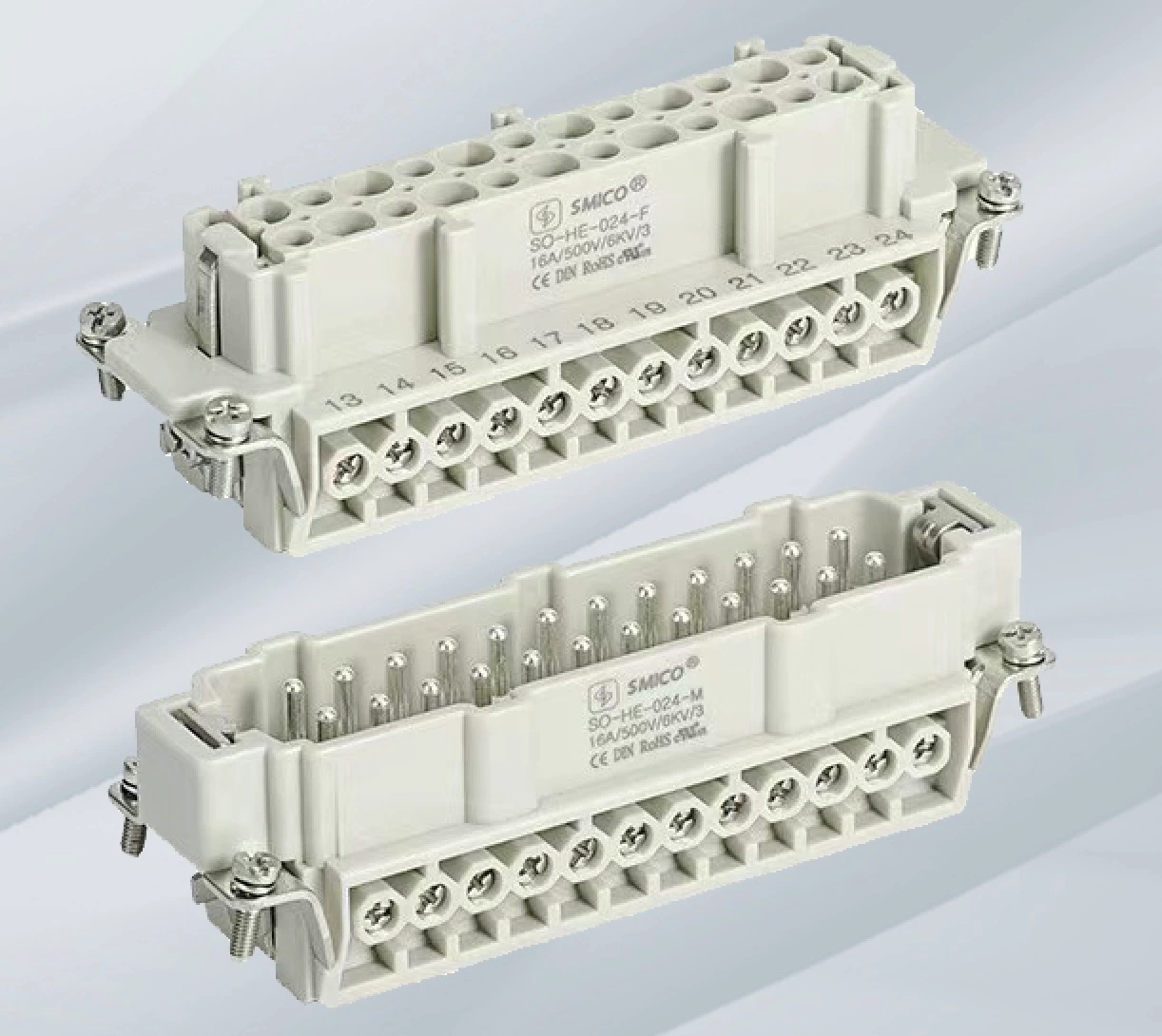

First, the screw connection method.

Suitable for HA, HE, HVE, HSB, HK, HEAV, HM series connector cores.

| Connector insert | Wire diameter | Wire stripping | |

| mm² | AWG | ||

| HA-003 HA-004 | 2.5 | 14 | 4.5 |

| HE HA HEAV | 2.5 | 14 | 7.5 |

| HE | 4.0 | 12 | 7.5 |

| HSB | 6.0 | 10 | 11.5 |

| HK | 16.0 | 5 | 14.0 |

Screw-type pins are popular among customers because of their convenient use, high efficiency and low installation cost. The advantages are as follows:

1. No need for special tools, just use an ordinary screwdriver;

2. Easy to install, installation personnel do not need professional training,

3. The connection is reliable, and the connection method has been recognized worldwide, approved by VDE, SEV, CSA, UL,

4. It is suitable for a wide range of wires, and can be equipped with wire protection sheets;

5. Applicable to all single-core wires and stranded wires;

6. No special treatment is required for the wires, only the insulating rubber needs to be removed.

7. Because the core itself has pins, for users, the material is less and it is easy to manage.

Cold press connection.

Suitable for HA, HE, HVE, HEE, HD, HDD, HK, HM, HQ and other series of connector cores.

Cold-pressed pins are popular among customers because of their convenience and efficiency, and their advantages are as follows

1. High pin density, close to cold welding, to ensure corrosion resistance;

2. The connection is reliable, and the connection method has been recognized worldwide and approved by VDE, SEV, CSA, UL;

3. Shockproof, widely suitable for vibration occasions;

4. The wiring harness can be pre-assembled;

5. The same ferrule can be used with different coating cold pressing pins according to actual needs.

Tools: cold pressing pliers, needle extractor

| Crimp contacts | Contact removal tools |

| 5A | TL08 |

| 10A | TL00 |

| 16A | TL01 |

| 40A | TL06 |

| 100A | TL07 |

The shrapnel connection method.

Suitable for HE, HK, HME series cores.

Shrapnel-mounted inserts are widely welcomed by customers because of their ease of use, high efficiency and low installation costs. The main advantages are as follows:

1. Basically, no special processing is required for the stripped wires, and the installation is fast and efficient;

2. No special tools are required, just use an ordinary flat-blade screwdriver (3.0x0.5mm), which is easy to install, and the wire and the insertion surface of the screwdriver are on the same plane;

3. The connection is reliable and can ensure the connection of low resistance. This connection method has been recognized worldwide and has been recognized by VDE, SEV, CSA, UL and other institutions;

4. Anti-vibration, suitable for various vibration occasions;

The bolt connection method.

Suitable for HK, HQV, HQ, HC series cores.

Axial bolt connection, the use of a wide range of wire specifications, no special tools, only need to be hexagonal, only a small space, simple and easy to operate.