New growth of heavy-duty connectors under Industry 4.0

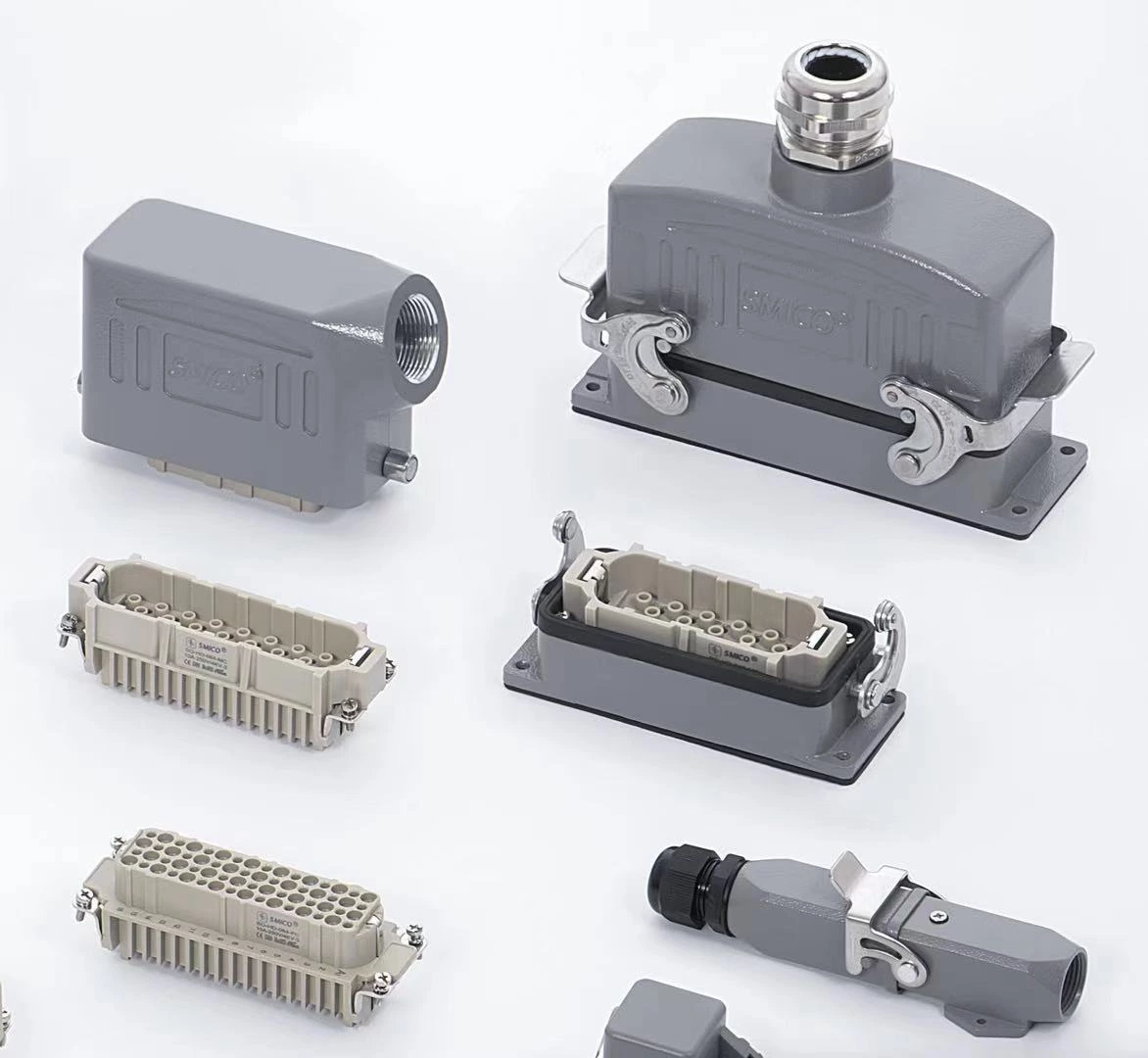

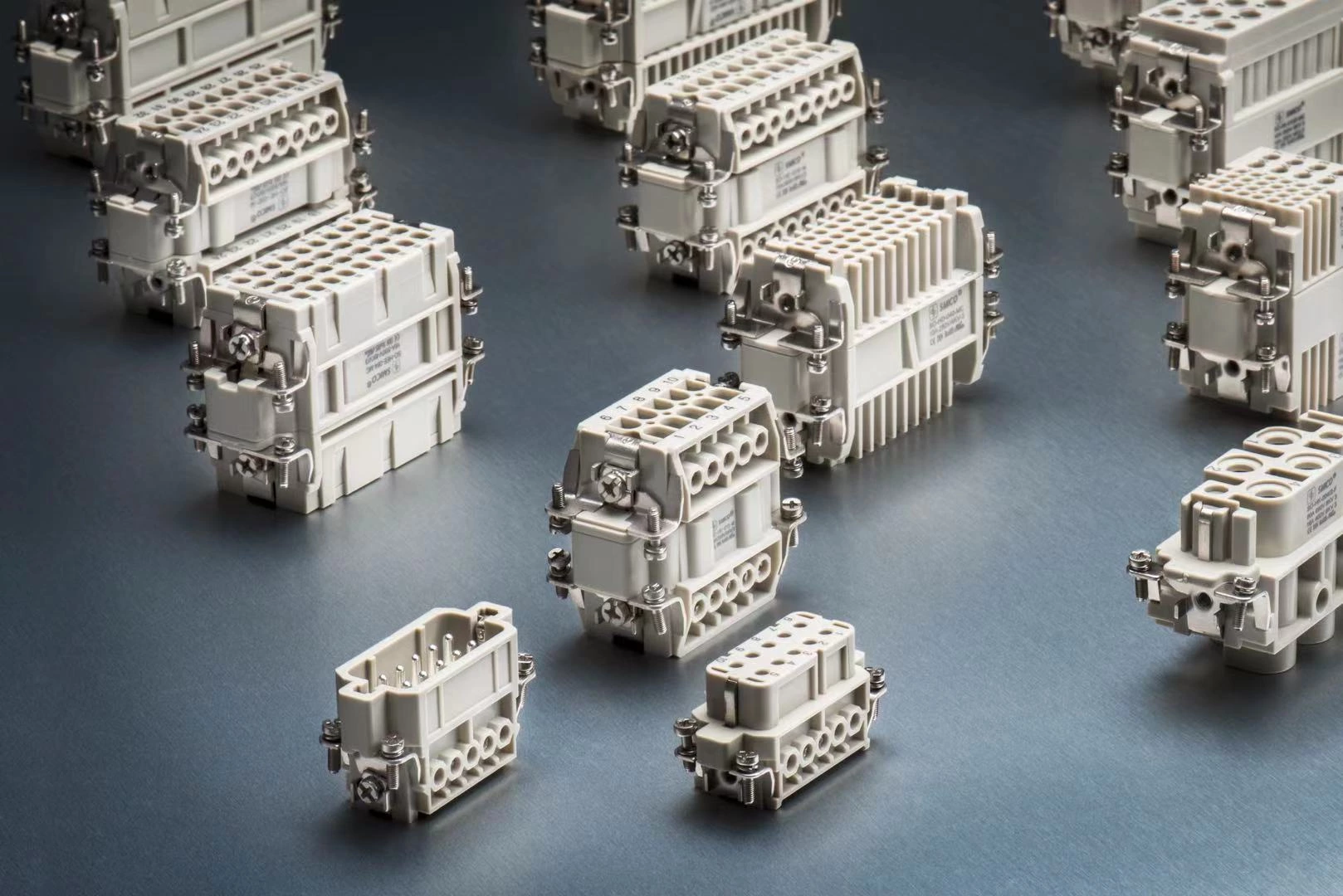

In the gradual development of heavy-duty connectors, structural design, modeling creation, technological innovation, etc. make it excellent in the use of electrical equipment, and can adapt to more complex use environments.

With the development of Made in China 2025 and Industry 4.0, the development of China's smart devices requires the use of connectors that are more suitable for actual needs. Traditional connectors are gradually unable to meet the diversified needs at this time. At this time, a heavy load should be born. The connector has its place.

Each series of SMICO connectors has dustproof, waterproof, shockproof and various high mechanical strain properties, and the waterproof protection can at least prevent water jets from any angle. At the same time, compared with traditional connectors, SMICO heavy-duty connectors can save installation costs, improve production efficiency, and increase the stability of the connection. It can be well applied in the mechanical automation, automotive industry, electric and wind energy, and rail transit industries.

With the continued advancement of Made in China 2025 and Industry 4.0, as a key component of connecting equipment and equipment, traditional connectors will also face more and more stringent requirements. With a strong structure and sophisticated design, heavy-duty connectors will usher in a new round of demand expansion. Taking the lead in laying out the heavy-duty connector market under the wave of industrial automation may help companies grasp the ever-changing market environment.