Industrial robot connector, big wisdom in a small space

Robots are known as the crown jewel of modern manufacturing, and are the core component of the modern intelligent equipment industry, supporting the transformation and upgrading of the manufacturing industry, and occupying an important position in all walks of life. As one of the key components of the robot, the connector provides power, signal and network transmission for the robot, and plays an indispensable role in promoting industrial automation production.

Robot Connector Requirements

In recent years, with the continuous development of industrial automation, robots have ushered in a huge market demand and put forward higher requirements for connectors. Facing the opportunities and challenges brought by the times, HARTING has continuously innovated and carried out technology research and development. It has successively launched modular connectors for power and signal transmission between control cabinets and robots, and high pin HDD connector. Continue to lead the connector industry towards the direction of modularization, miniaturization, high speed and high integration, empower the development of the robot industry, and meet the changing market demands.

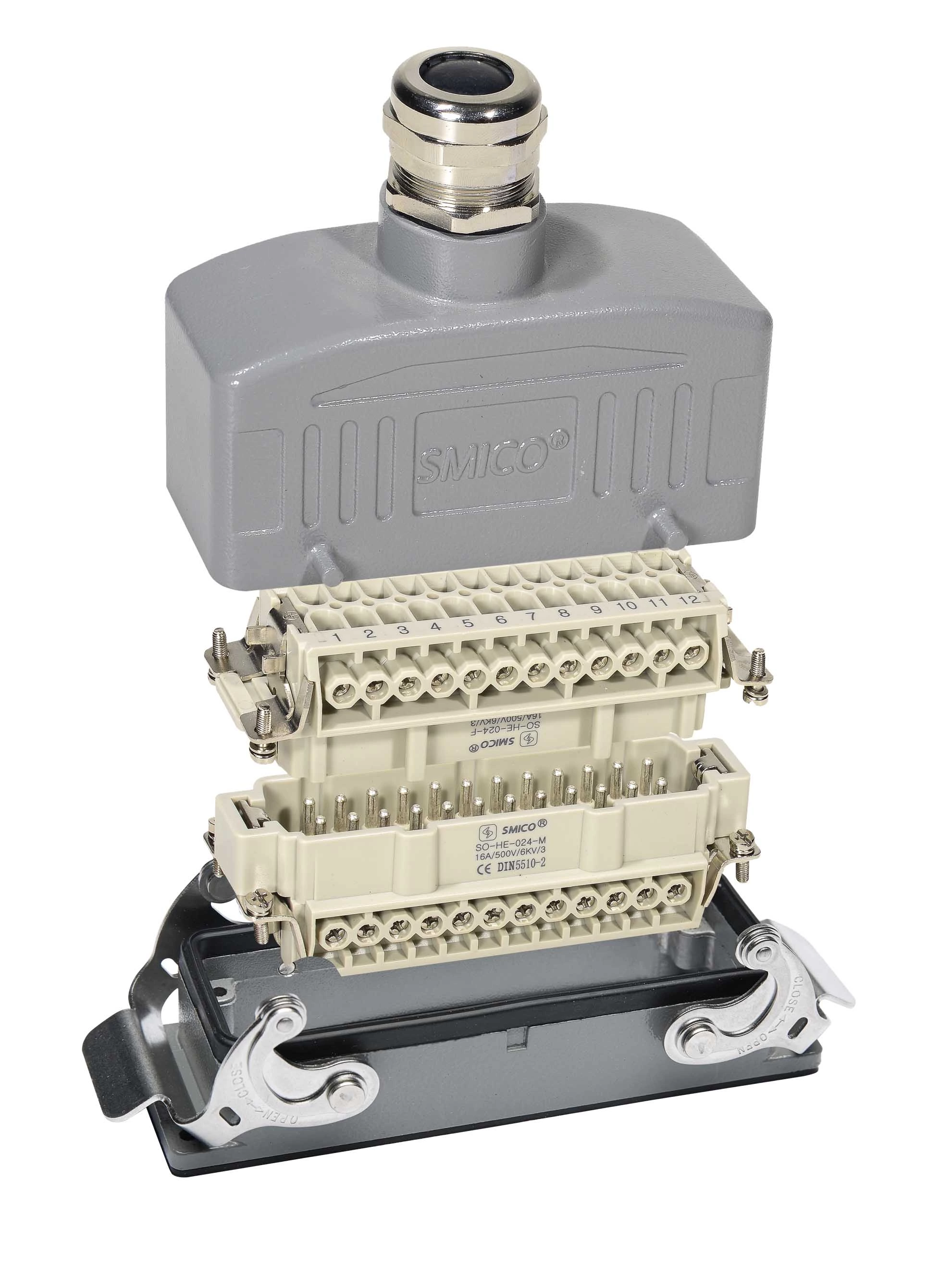

Mixed Configurations Create More Possibilities

Robot manufacturers face two main challenges when developing new application areas such as assembly lines:

●On the one hand, robots need more and more sensitive sensors;

● On the other hand, connectors are required to be increasingly miniaturized and flexible enough to perform more and more complex assembly operations.

Modular connectors are an excellent choice to support the development of such robotic systems by accelerating miniaturization and ensuring shielded data transfer.

The modular connector Han® DD Double Module can provide up to 36 10A / 400V Han® D-type pressure pin power connection points, while the Han® Shielded Module Basic and Plus shielded modules can provide 27 4A/32V power connections when fully loaded D-sub type indenter signal connection point. The common combination of these two modules can be applied to models such as small six-axis or SCARA with high requirements on space and shielding performance. To optimize the use of space in the connector, HARTING is continuously increasing the contact density of the Han-Modular® modules.SEO设置

Big wisdom in a small space

Space-saving connector solutions are particularly important in many mechanical, robotic and automation applications, which is why HARTING is promoting the Han® DDD connectors with high pin density and small dimensions. Compared to the previous standard Han® DD, the pin density of the Han® DDD has been increased by up to 130%, but the voltage rating has not been reduced, while maintaining the same dimensions and electrical characteristics.

In addition to saving space, HARTING also offers accessories such as grip panels and guide pins/bushings for Han® DDD ferrules to help optimize the wiring process. No additional accessories and tools are required for the installer, and only one electrical and ground pin termination technique needs to be dealt with to complete the wiring. Therefore, Han® DDD is extremely convenient to use in conventional control cabinets, and provides users with the possibility of more connection points without changing the size of the existing connection panel openings of the robot. Not only that, but in all industrial fields involving electrical connections, the space-saving design concept of Han® DDD is very forward-looking and practical, and the market potential is huge.

At present, industrial robots are being used in various fields of manufacturing, becoming an important entry point for a new round of global technological and industrial transformation