Industrial Connectors

Heavy Duty Connector provides years of service in a typical office environment. However, expose the same copper or fiber connector to extreme conditions and its performance and reliability will degrade, leaving the end user with expensive maintenance costs to troubleshoot and replace parts. A new connector, designed specifically to create a rugged Ethernet connection in harsh environments, is tougher, stronger and more resistant than previous connectors. This new interface is widely considered an "industrial connector" and its applications are not limited to manufacturing. This connector is designed to withstand the harshest industrial environments.

Industrial Connector Solutions Have Been

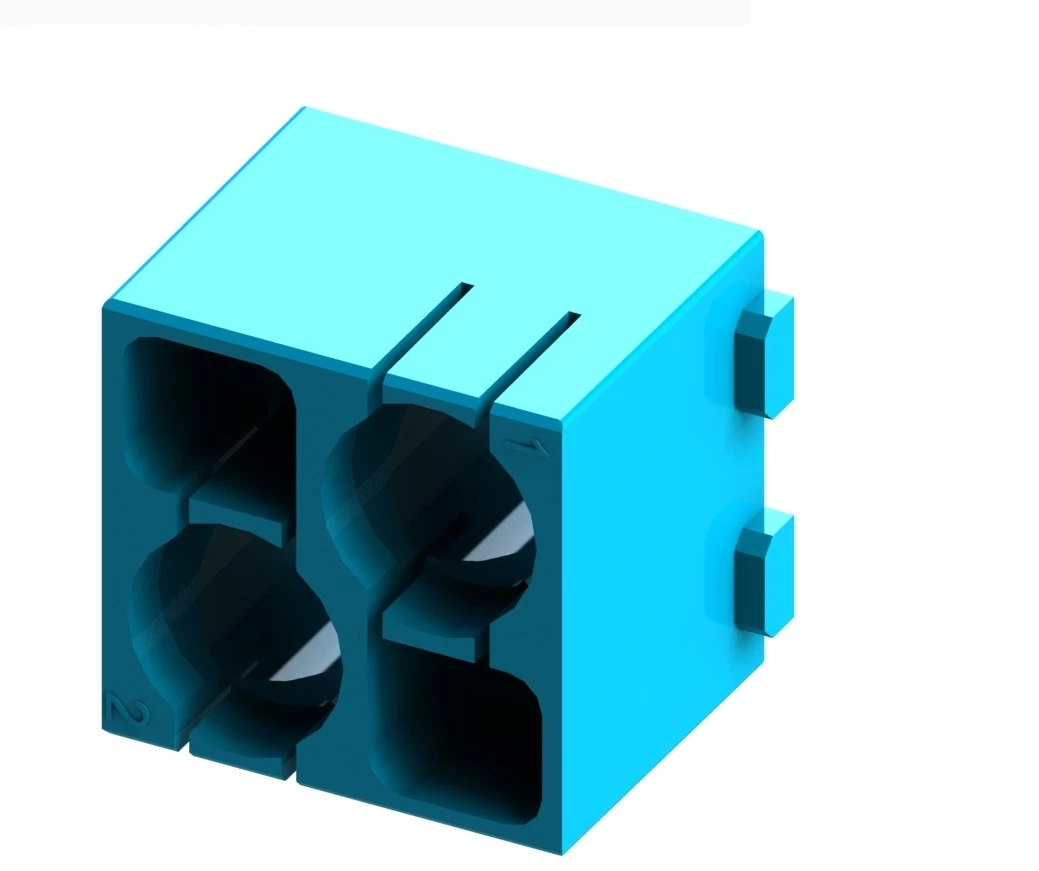

An industrial RJ-45 connector that meets all TIA and IEC draft standards requirements and is approved by the ODVA organization. Siemon's Industrial MAX jacks and plugs provide very effective protection against extreme environments.

Siemon's industrial solution focuses on a sealed RJ-45 plug and jack to achieve an IP 67 rating. The exterior of the plug has a unique bayonet-style coupling nut that engages the jack housing with a simple quarter-turn rotation. RJ-45 plugs and jacks meet enhanced Category 5 requirements, are field installable, and can be assembled with jumpers of appropriate lengths on site. The mating engagement pattern prevents the effects of moisture or direct contact with liquids. In addition, this pattern resists damage to the conductor pins of the socket by maintaining the relative position of the plug to the socket. Simon Industrial MAX design uses materials that are more resistant to chemicals and have a wider range of operating temperatures than traditional connectors. Finally, for high EMI environments, Simon provides shielded (ScTP) industrial connectors that have both high shielding efficiency and low transmission impedance to protect data signals from horizontal cables to equipment jumpers.

Installation Challenges

Implementing and installing Ethernet/IP is not without challenges. A common problem is the lack of trained engineering personnel who have both IT background and understanding of automation control networks. Automation teams and IT personnel must work together to install and implement an Ethernet/IP system. Proper network configuration is the second challenge. Once properly installed, Ethernet/IP requires little maintenance.