Importance Of Heavy Duty Connectors

Heavy Duty Connector, meet diversified connection needs

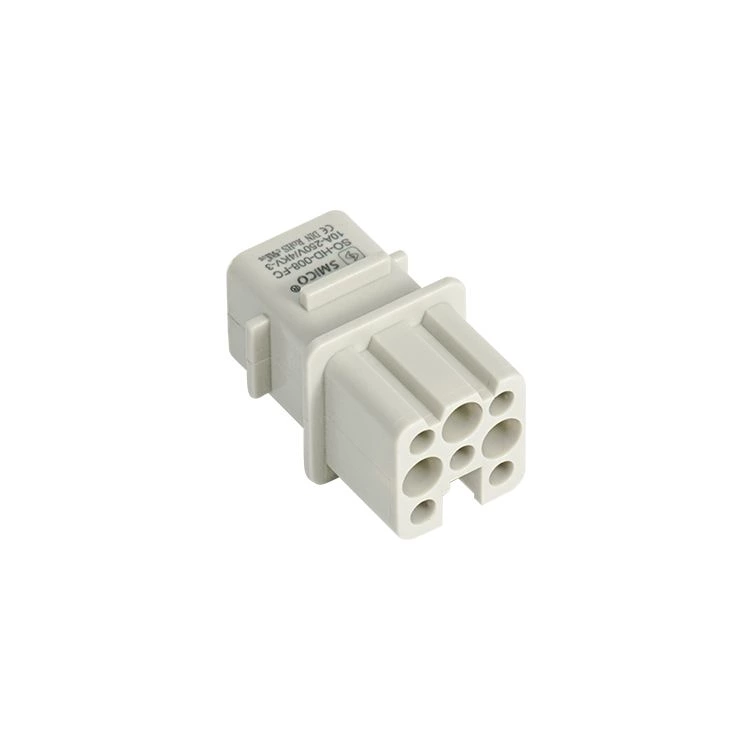

The heavy-duty connector adopts a modular design and continuously expands its functions according to the needs of the application. It not only realizes barrier-free and fast connection between modular devices, but also ensures the transmission of signals and power supply, meeting the diversified connection needs of users.

For mechanical equipment manufacturers, it can save installation time, safe and reliable connection, and reduce comprehensive production costs. For terminal users, they can freely install and operate equipment without any professional guidance, and maintenance becomes simple.

Its advantages are mainly reflected in the following three aspects:

The pre-installation of a large number of complex circuits greatly improves the installation efficiency of the equipment and reduces the wiring error rate.

Provide highly integrated connections, and rich combinations maximize the effective utilization of equipment space.

Conveniently and efficiently realize the modular structure of each functional template block of the equipment, so that the equipment can be conveniently and safely transported, installed, maintained and repaired.

Compared with traditional connection methods, the use of heavy-duty connectors can save 20-30% of the installation cost for the processing center, while increasing production efficiency. It is mainly used in industrial automation, equipment manufacturing, industrial system buildings, information and control technology and other fields.