High-density Heavy-duty Connector, Full Coverage Of Electrical Performance

As a Heavy Duty Connector designed to transmit power, data and signals under harsh conditions, it targets harsh robot conditions such as vibration, dust, temperature challenges and mechanical shock. Today, with various flexible modular trends and the upgrade of hybrid transmission, heavy-duty connections can not only solve high-power transmission under harsh working conditions, but also be flexible enough.

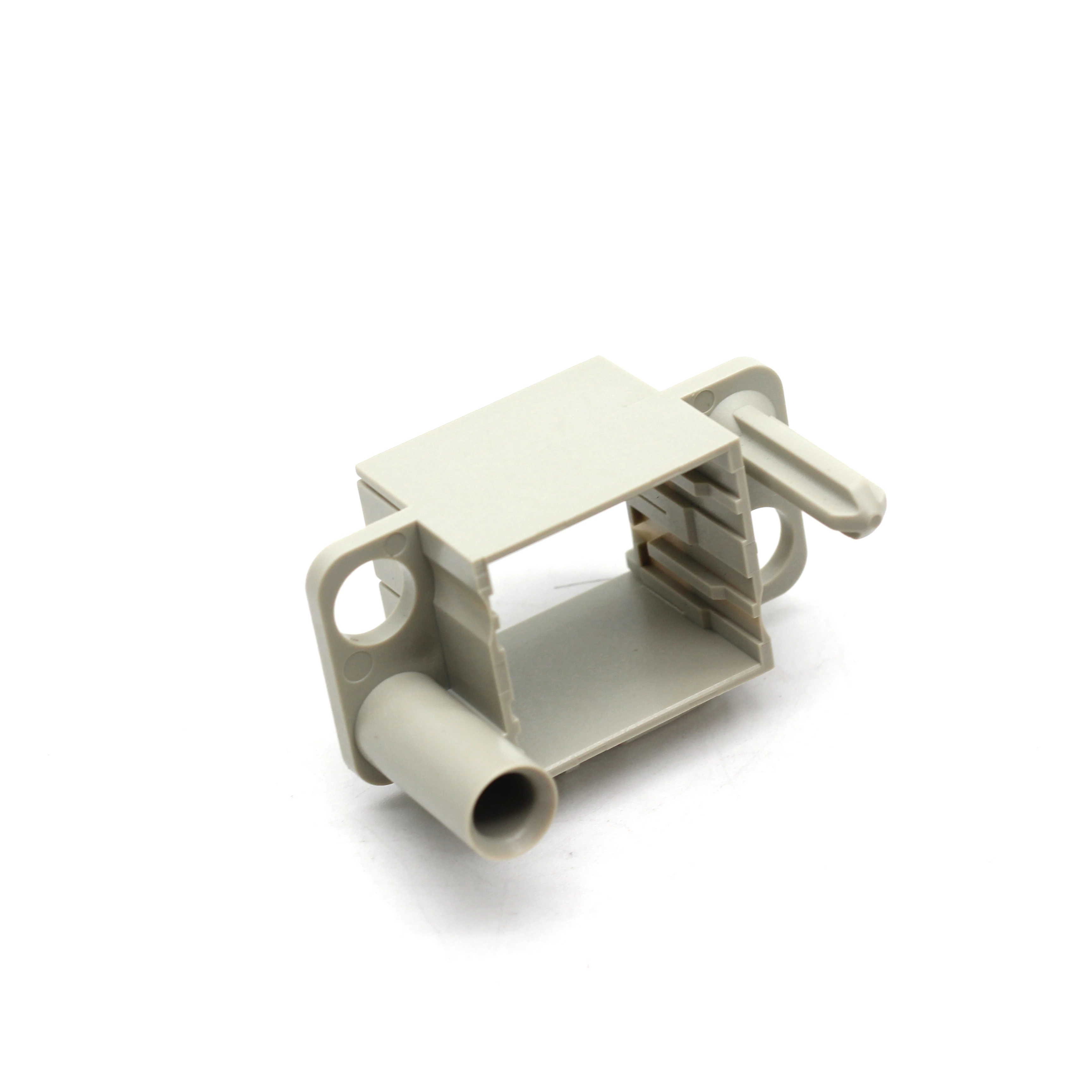

Hybrid transmissions first solve the space problem. With the help of modular systems, heavy-duty connectors can combine various power, signal and data transmission technologies (RJ45, D-Sub, USB, Kinte, fiber optic), greatly saving the connection size. Simply saving size is not a big advantage. In a single connector, the high density of signal terminals is an attraction point for larger sizes in limited space. If the heavy-duty connector module is fully configured, its signal terminals can reach hundreds of pins, and the high density is self-evident.

The heavy-duty connection with high-performance and high-density electric shock structure covers a wide range of electrical performance of the entire robot system, and can easily carry a current range of several amperes to hundreds of amperes. Moreover, the customization of heavy-duty connections can not be limited to one signal or data transmission, and can realize the connection of signals, power, pneumatics, coaxial cables, Ethernet, etc. Heavy-duty connections are very popular for industrial robots that need to work in harsh conditions.