Heavy-duty Connectors: Safety Assurance For Industrial Electrical Connections

In modern industrial and electrical applications, Heavy Duty Connector plays a vital role. Whether in manufacturing, construction or energy industries, these connectors are the basis for achieving safe and stable electrical connections. This article will explore the definition, application scenarios, working principles and factors to consider when selecting heavy-duty connectors.

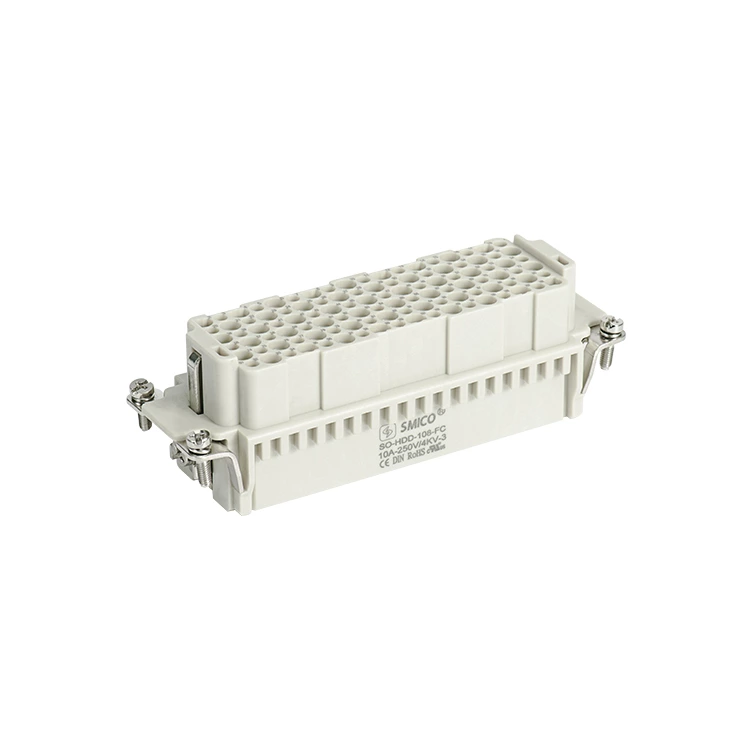

What is a heavy-duty connector?

Heavy-duty connectors are electrical connectors designed to withstand high currents and high voltages. Compared with ordinary connectors, they have stronger mechanical and electrical performance and can maintain stable connections in harsh environments. Heavy-duty connectors are usually made of sturdy materials to ensure durability and reliability. These connectors can withstand frequent plugging and unplugging operations while providing good protection against water and dust.

Application scenarios

Heavy-duty connectors are widely used in multiple industries, including but not limited to:

Energy industry: In wind, solar and traditional power stations, heavy-duty connectors are used to connect generators, transformers and distribution systems. These connectors must be able to withstand high currents to ensure the safe transmission of electricity.

Manufacturing: In automated production lines, heavy-duty connectors connect various devices and sensors to ensure the normal operation of machinery and equipment. These connectors need to have vibration and wear resistance to adapt to high-speed working environments.

Construction industry: At construction sites, heavy-duty connectors are often used to connect temporary power supplies. These connectors can establish safe and stable electrical connections between different electrical equipment to ensure normal operation of the construction site.

Transportation industry: In the railway and aviation fields, heavy-duty connectors are used for the power supply of vehicles and equipment to ensure that there is no poor contact problem during long-term operation.

Working principle

The working principle of heavy-duty connectors mainly depends on their design structure. Usually, they consist of two parts, a plug and a socket, and an electrical connection is formed by plugging and unplugging. The internal structure of heavy-duty connectors is usually designed with multi-point contact to increase the contact area, reduce contact resistance, and thus improve conductivity. In addition, many heavy-duty connectors are also equipped with an anti-reverse plug-in design to ensure the correctness of the connection and prevent equipment damage caused by wrong connection.