Heavy-duty Connectors: Providing Strong Support For Industrial Automation

In modern industrial automation and electrical engineering, connectors play a vital role. They are key components to ensure that equipment and systems can operate efficiently, safely and reliably. As a type of connector, heavy-duty connectors are widely used in various harsh industrial environments due to their superior load-bearing capacity and durability. Especially in the fields of power, railways, metallurgy, mining, etc., heavy-duty connectors play an irreplaceable role.

Features and advantages of Heavy Duty Connector

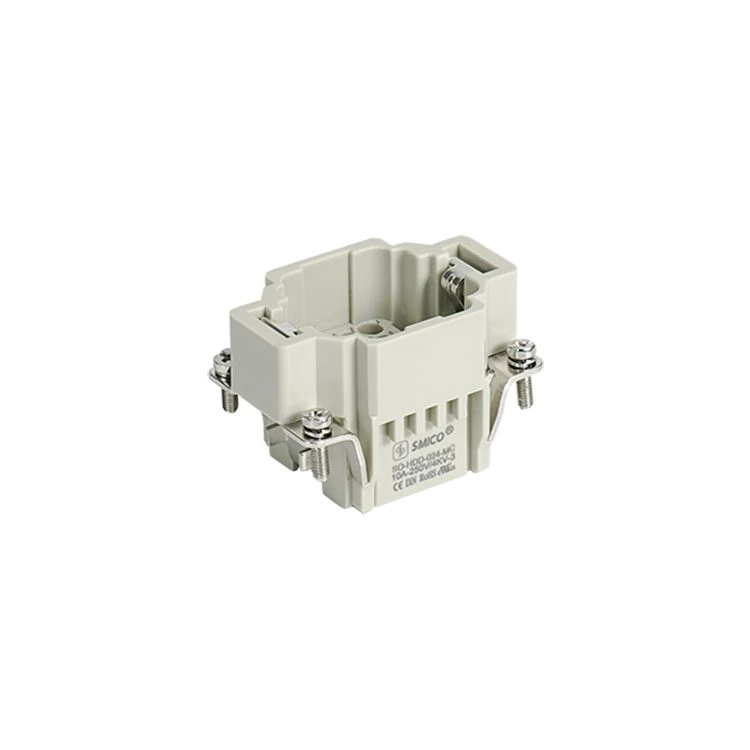

Heavy-duty connectors are mainly used for equipment connection under high current, high voltage and complex environmental conditions. Compared with traditional connectors, heavy-duty connectors have stronger load-bearing capacity and higher durability, and can adapt to the use requirements in extreme environments. They can not only withstand higher mechanical loads, but also prevent the influence of external environmental factors (such as vibration, impact, dust, moisture, etc.) on the connection.

First of all, the material of heavy-duty connectors is usually corrosion-resistant and oxidation-resistant alloys and plastic materials to ensure long-term and stable operation in harsh working environments. Secondly, their design takes higher safety into consideration. Many heavy-duty connectors are equipped with waterproof, dustproof, shockproof and other functions to meet the application requirements in different environments. In addition, heavy-duty connectors have a long service life and strong maintainability, greatly reducing equipment downtime and maintenance costs.