Heavy-duty Connectors: Improving Electrical System Stability And Safety

As an indispensable and important component in the electrical system, Heavy Duty Connector is widely used in various industrial and power equipment. The core function of these connectors is to realize the transmission of electrical signals and the connection of power, and to ensure stability and safety under high load conditions. With the gradual upgrading of industrial equipment and the increasing demand for high-efficiency electrical products, the technology and application of heavy-duty connectors are also constantly developing towards higher standards, becoming one of the key technologies in the electrical industry.

Working principle and application of heavy-duty connectors

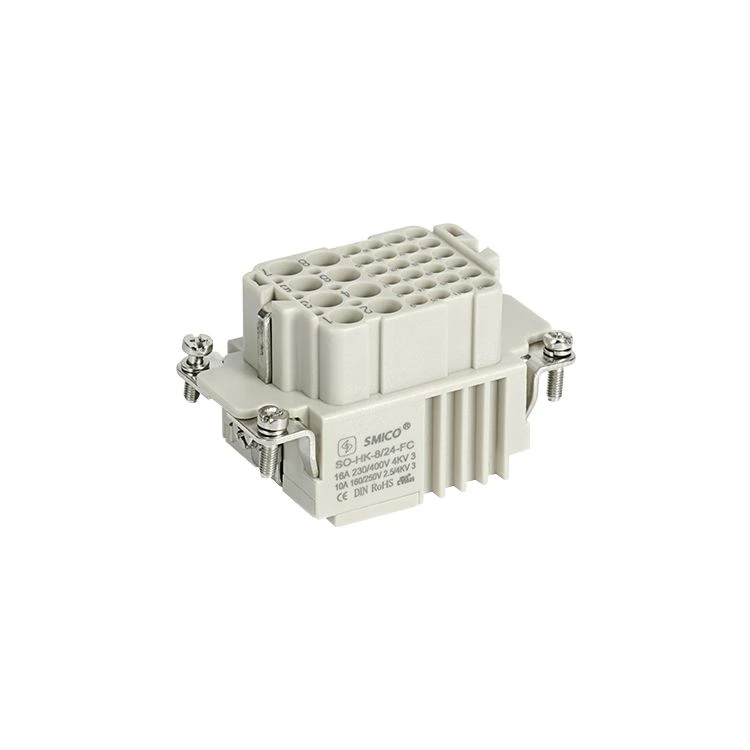

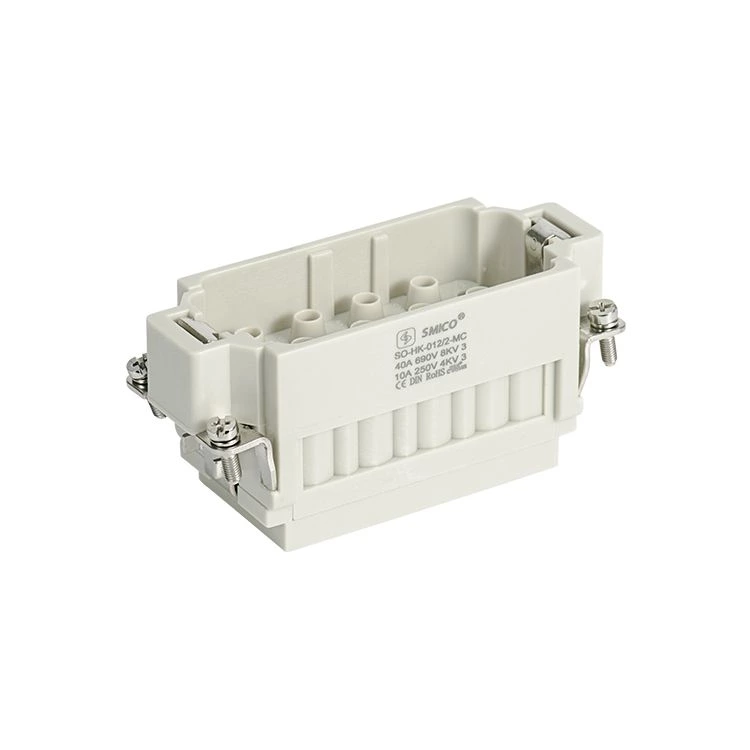

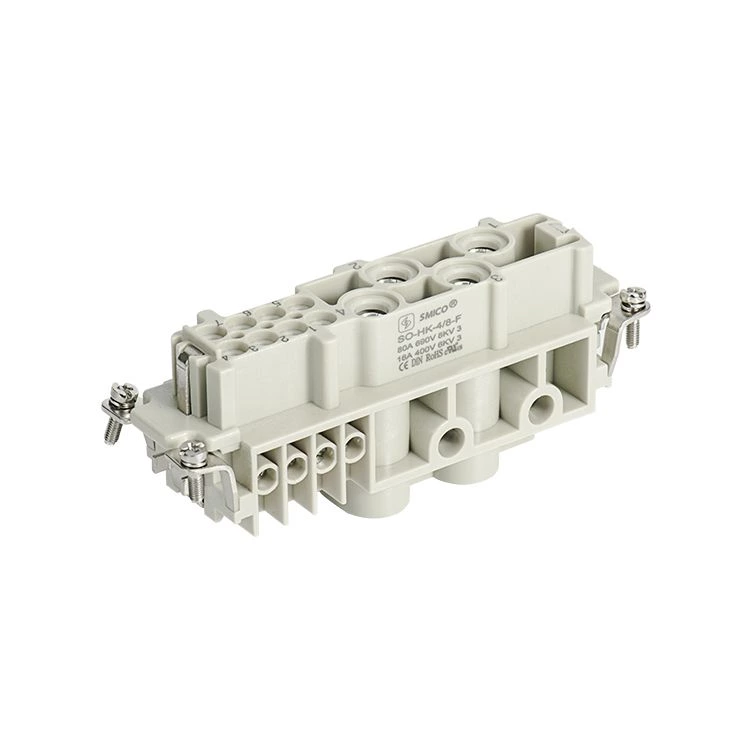

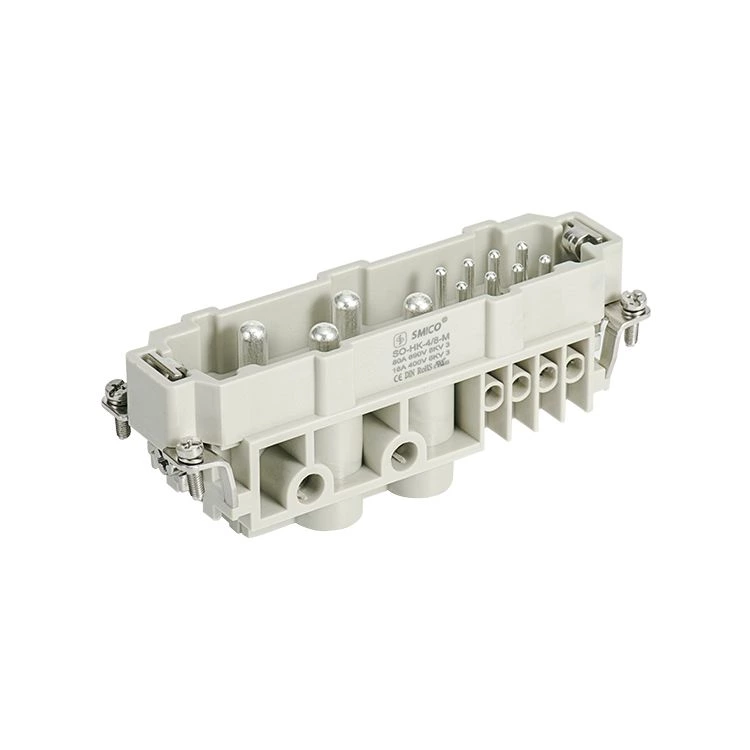

Heavy-duty connectors are usually composed of plugs, sockets, contacts and other parts, and are designed with high-strength materials to ensure that they can still maintain excellent transmission performance under high current and high temperature environments. These connectors are mainly used in high-power transmission and control systems in electrical equipment. They can provide stable current and signal transmission, ensure the normal operation of equipment, and prevent power failures or equipment damage caused by poor contact.

Especially in the fields of industrial automation, communications, power facilities, and high-frequency electronic equipment, the application of heavy-duty connectors is particularly important. For equipment in these fields, connectors are required to withstand large current shocks and frequent use, while ensuring stable connections and strong anti-interference. Therefore, heavy-duty connectors must have extremely high durability and reliability to meet the high standards of electrical components in modern industrial production.