Heavy-duty Connectors Allow Users To Enjoy A More Efficient And Convenient Experience

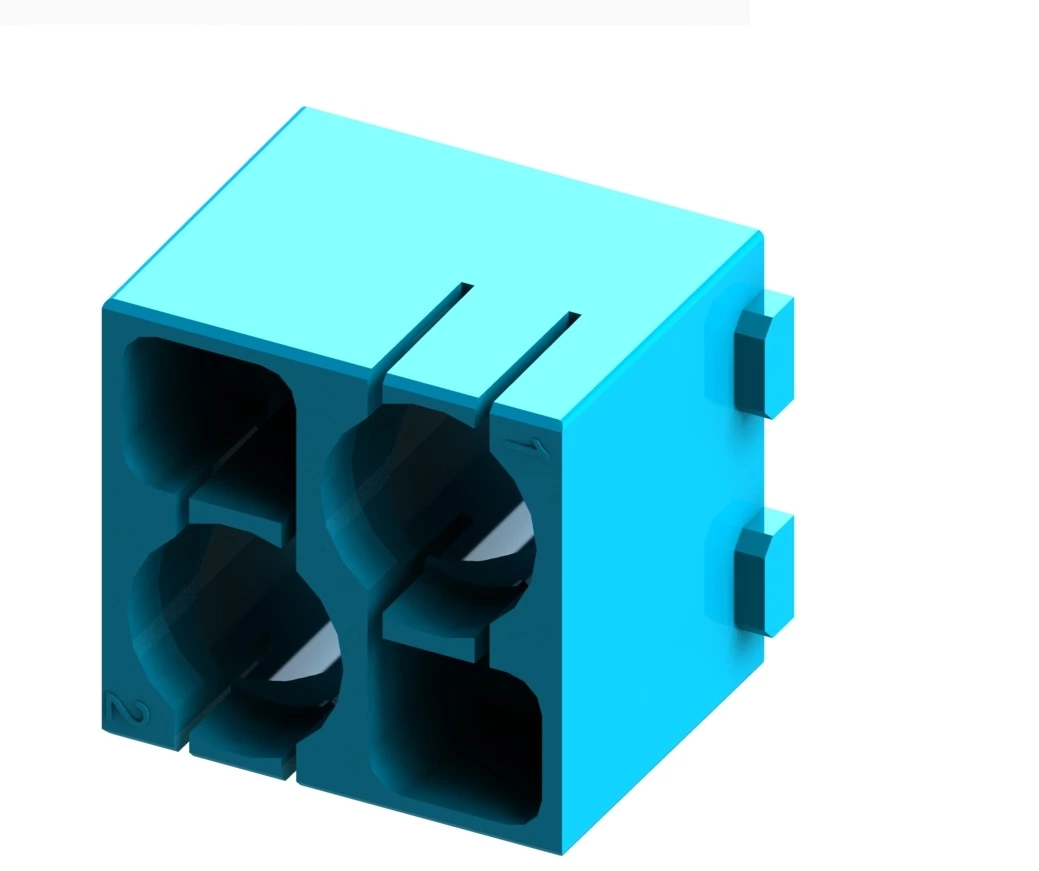

1. Heavy Duty Connector is designed to withstand the harshest and most demanding industrial environment. It is tougher, stronger and more resistant than ordinary connectors. 2. Compared with traditional connection methods, the use of heavy-duty connectors can save 20-30% of the installation cost for the machining center; increase production efficiency and reduce the error rate of wiring. 3. The international advancement of heavy-duty connectors in structural design and material use makes the connector outstanding in electrical performance. The reliability of the electrical connection system is unattainable by traditional connection methods. 4. The heavy-duty connector adopts a modular design, which includes pneumatic modules, high current modules, profibus Dp bus modules and USB interface modules. When using modular devices, it can be connected quickly and without obstacles. Therefore, compared with ordinary connectors, it is more practical and more convenient to maintain. Connectors are really a big family. This article mainly introduces the relevant knowledge of heavy-duty connectors. Heavy-duty connectors are definitely quite important in connectors. Because it is designed to withstand the test of harsh industrial environments, it is widely used in construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, robots, rail transportation, hot runners, electricity, automation and other equipment that require electrical and signal connections. It is tougher, stronger and more resistant than other brothers and sisters.