Heavy-duty Connector Pollution Level Introduction

Heavy Duty Connector products all have pollution level characteristics. If the pollution level of heavy-duty connectors is relatively high, you should pay attention to it during use. So what is the pollution level of heavy-duty connectors? Let's take a look.

Pollution level I has no pollution or only dry non-conductive pollution, no impact. Such as machine rooms, measuring equipment rooms, etc.

Pollution level II represents only non-conductive pollution, but occasional short-term conductive pollution must be expected. For example, residential, commercial buildings, laboratories, precision machinery workshops, etc.

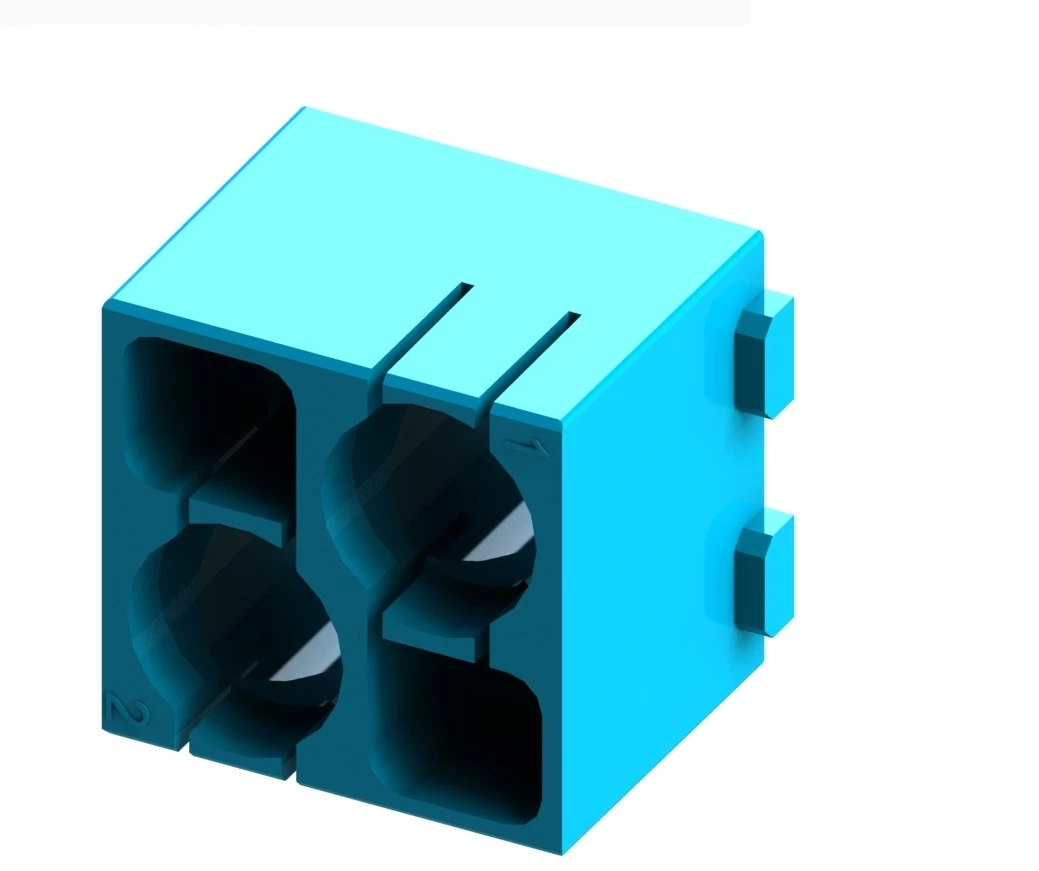

Pollution level III has conductive pollution or dry non-conductive pollution becomes conductive pollution due to expected condensation. Such as warehouses, workshops or boiler rooms without heating, as well as electrical equipment or machine tools in units. Keri industrial connectors are designed according to this pollution level.

Pollution level IV causes persistent conductive pollution in enterprises, such as students caused by conductive dust or rain and snow. Such as in open air or outdoor activity spaces, train information or roof equipment of trams.

Heavy-duty connectors are used in many places, so it can be seen that the application of heavy-duty connectors is very extensive. Let us have a detailed understanding of it! Today, any industry is moving towards automation, and even traditional connectors are outdated. The emergence of this overload connector provides new options for more and more industries. Whether it is the textile industry, robots and automation equipment, there is a demand for it, which is enough to show that the various industries where connectors are applied are very common.

It is precisely because of the extensiveness of heavy-duty connectors that companies have saved a lot of trouble. In the past, they have been looking around for equipment suitable for their own companies. Now, as long as they have heavy-duty connectors, they don’t have to worry about anything. They can manage a large number of complex circuit pre-installations, greatly improve the installation efficiency of equipment, reduce errors in wiring, and effectively utilize the entire equipment space with highly integrated connections and rich combinations. In addition, the current heavy-duty connectors are widely used in the field of power transmission and distribution. It can provide a certain degree of protection, and will not be affected no matter how bad the weather is. Through the above introduction, you should know why heavy-duty connectors are so widely used!