Heavy-duty Connector Manufacturers: Pioneers And Challenges In The Industry

In modern industry and high-tech fields, Heavy Duty Connector plays a vital role. As key components of connections and electrical interfaces, they ensure stable operation and efficient transmission of equipment in various complex environments. This article will explore in depth the industry status, technological development and challenges faced by heavy-duty connector manufacturers, as well as their potential and opportunities in the future market.

Definition and application of heavy-duty connectors

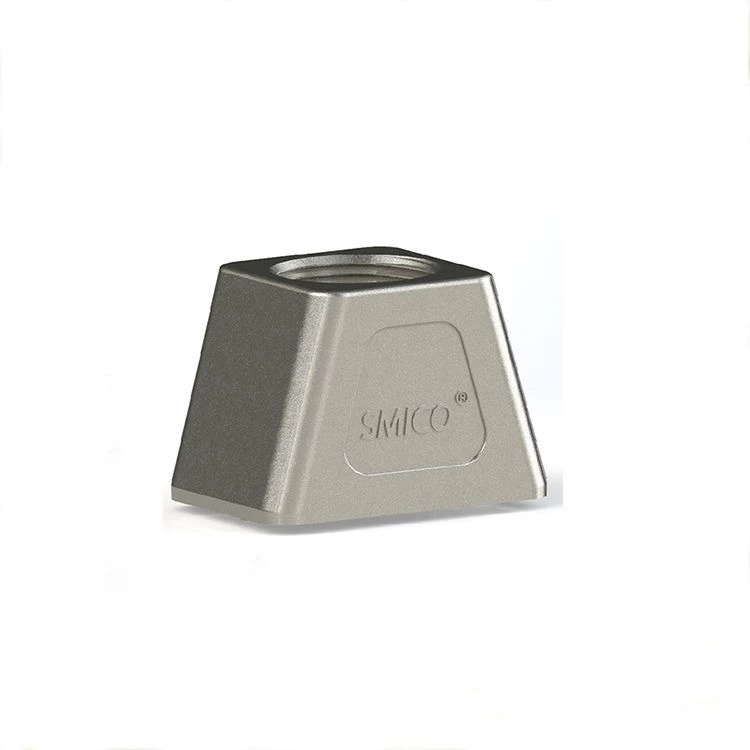

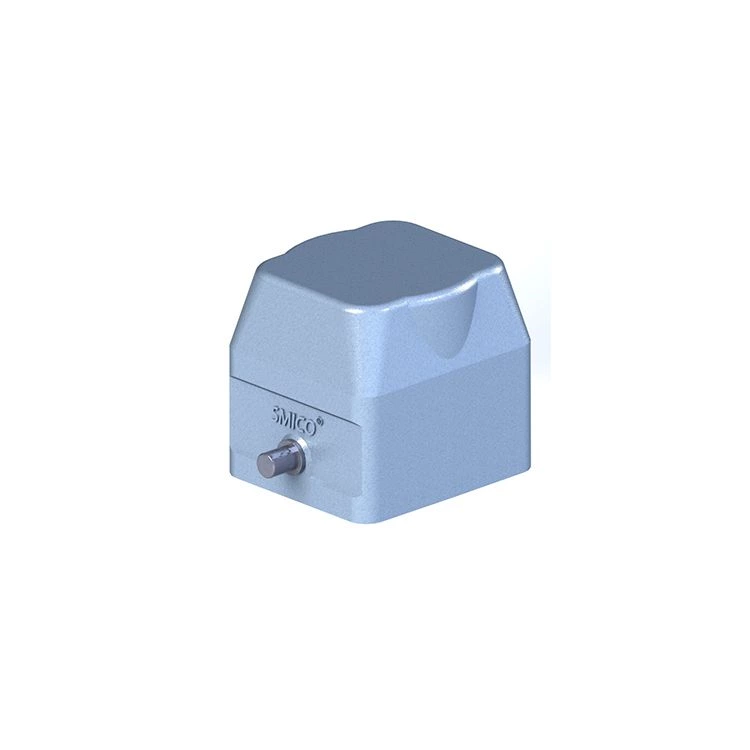

Heavy-duty connectors are connectors designed to withstand high currents, high voltages and harsh environmental conditions. Compared with ordinary connectors, they usually have stronger mechanical strength, durability and protection capabilities. This makes them widely used in industrial automation, railway transportation, aerospace, energy and power and other fields. In these fields, heavy-duty connectors not only need to withstand extreme physical and electrical loads, but also maintain stable performance under harsh environmental conditions.

Technological development of heavy-duty connector manufacturers

With the continuous advancement of science and technology, the design and manufacturing technology of heavy-duty connectors are also constantly developing. On the one hand, the innovation of manufacturing materials has improved the durability and reliability of connectors. For example, the application of new alloy materials and high-strength plastics has improved the performance of connectors in high temperature, high humidity, high vibration and other environments. On the other hand, the advancement of precision machining technology has made the plug-in and unplug performance of connectors more stable and the contact resistance lower.

In addition, the introduction of intelligent technology is also a major advancement in the field of heavy-duty connectors. By integrating sensors and communication modules, modern heavy-duty connectors can monitor the connection status in real time and provide fault warnings, further improving the safety and maintenance efficiency of the system.

Market challenges for heavy-duty connector manufacturers

Although technological advances have brought many opportunities, heavy-duty connector manufacturers also face many challenges in market competition. First, the market has higher and higher requirements for heavy-duty connectors, which not only need to meet basic performance indicators, but also have higher reliability and intelligent functions. In order to meet these requirements, manufacturers need to continue to invest in research and development to maintain their technological leadership.

Secondly, fluctuations in raw material prices and rising production costs are also important factors affecting heavy-duty connector manufacturers. Especially in the context of increasing global economic uncertainty, manufacturers need to effectively manage the supply chain and control costs to maintain their competitive advantage.