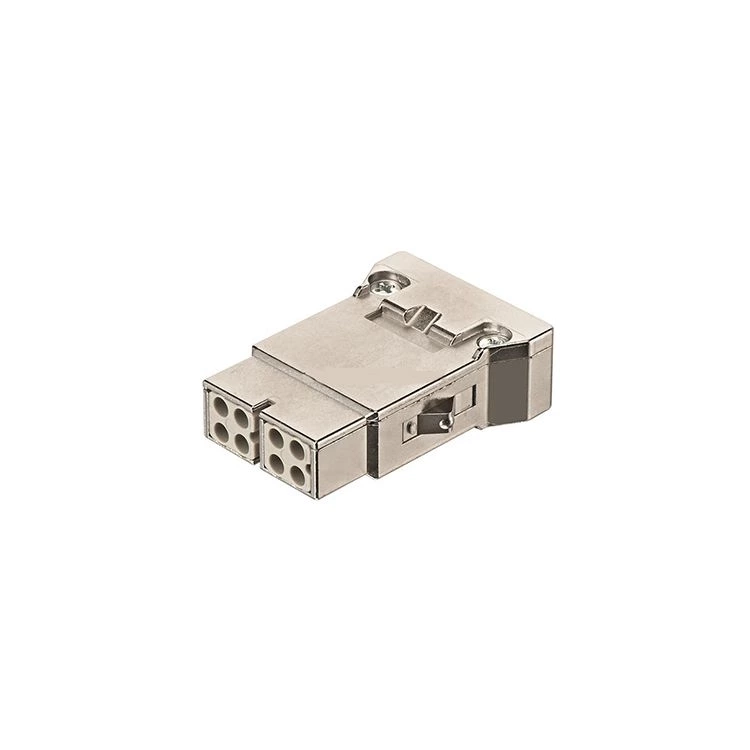

Heavy duty connector Innovative And Efficient Pneumatic Technology

Heavy duty connector Innovative And Efficient Pneumatic Technology

With the continuous development of industrial automation, connector products have become more diversified and innovative. In response to the needs of plugging and unplugging, SMICO Electric provides three series of pneumatic options.

1) The plastic plug (bracket) is covered with ORING. Under the action of spring force and high-pressure gas, the outer diameter of ORING is tightly pressed against the internal inclined surface of the female end to achieve the sealing of the female end. 2) Before the plastic plug (bracket) is pushed open at the top of the male end, the ORING on the outside of the male end has been sealed with the inner wall of the inner hole of the female end. When the male end pushes open the plastic plug (bracket), the high-pressure gas is connected. 3) When the male end pin is pulled out, the plastic plug (bracket) on the female end returns to the initial sealing state. That is, a cycle of plugging and unplugging is completed.

Male and female plug-in times Air pressure up to

500 times 8bar

500 times 10bar

1. Efficient, durable, stable and reliable. WAIN pneumatic needle has a reliable structure and can meet the operational requirements of high-pressure plugging and unplugging. At the same time, WAIN provides a variety of connection solutions to adapt to various connection scenarios, with high adaptability and flexibility.

2. Innovative design, convenient operation. WAIN provides three series of pneumatic needles to choose from. The second and third series provide quick-connect models, striving to make operation more convenient. In addition, the third series changes the male needle interface design based on the second series, reducing the male and female plug-in operation force.

3. Adapt to diverse needs. In different application scenarios, pneumatic needles require different operating modes. The female end of the WAIN pneumatic needle can be optionally equipped with a non-locking state, making the pneumatic needle more flexible and able to adapt to more diverse work needs.

Pneumatic needles are used with pneumatic modules, and are combined with frames and all other module products. Which are widely used in aerospace, rail transportation, machinery manufacturing, wind power energy, robotics, automation and other fields.