Heavy Duty Connector Applications

Heavy-duty connectors are used in industrial applications such as railways, high-current connectors for communications, PC board connectors, coaxial cable connectors, backplane connectors, high-frequency converters, etc.

16-core socket, 4-core socket, 5-core hot runner socket

A. Inner core technical parameters: Working voltage: 230V Working current: 10A Flame retardant grade (according to UL94): V0 Wiring form: Screw crimping (0.5-4.0mm2)

B.Heavy Duty Connector technical parameters: Pollution level: 3 (C) Protection level: IP65 Upper shell cable entry thread: PG11

16-core hot runner socket

A. Inner core technical parameters: Working voltage: 400V Working current: 16A Flame retardant grade (according to UL94): V0

Wiring form: Screw crimping (0.5-4.0mm2)

B. Shell technical parameters: Pollution level: 3 (C) Protection level: IP65 Upper shell cable entry thread: PG21

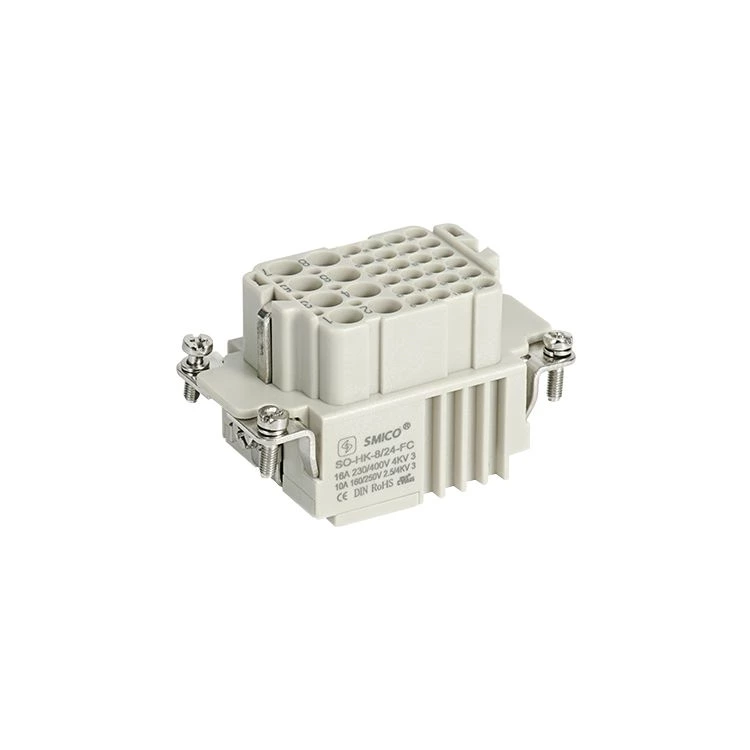

24-core hot runner socket

A. Inner core technical parameters: Working voltage: 400V Working current: 16A Flame retardant grade (according to UL94): V0

Wiring form: Screw crimping (0.5-4.0mm2)

B. Shell technical parameters: Pollution level: 3 (C) Protection level: IP65 Upper shell cable entry thread: PG29

Heavy-duty connector industrial use This new interface is generally considered an "industrial connector" and its application is not limited to manufacturing. This connector is designed to withstand the test of the harshest industrial environments. Traditional connection equipment provides users with years of service guarantee in a typical office environment. However, exposing the same copper cable or fiber optic connector to extreme conditions will reduce its performance and reliability, and end users will have to pay expensive maintenance costs to troubleshoot and replace accessories. A new connector, which is specially designed to build a rugged Ethernet connection in harsh environments, is tougher, stronger and more resistant than previous connectors.

Heavy-duty connector application Heavy-duty connectors are widely used in equipment that requires electrical and signal connections, such as construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, electric locomotives and petrochemical electrical.

Advantages of heavy-duty connectors 1. Pre-installation of large quantities and complex circuits can greatly improve the efficiency of equipment installation and reduce the wiring error rate.

2. Heavy-duty connectors provide highly integrated connections, and rich combinations maximize the effective utilization of equipment space.

3. Heavy-duty connectors The connectors conveniently and efficiently realize the modular structure of each functional template block of the equipment, so that the equipment can be easily and safely transported, installed, maintained and repaired. Connectors are widely used in the field of power transmission and distribution.

4. The high protection level (IP65, IP68) provided by heavy-duty connectors is unparalleled for the advantages of equipment connection systems in harsh environments. Provide effective protection in harsh environments such as dust, rain, cold, ice and snow, and oil pollution.