Heavy Duty Connector Application

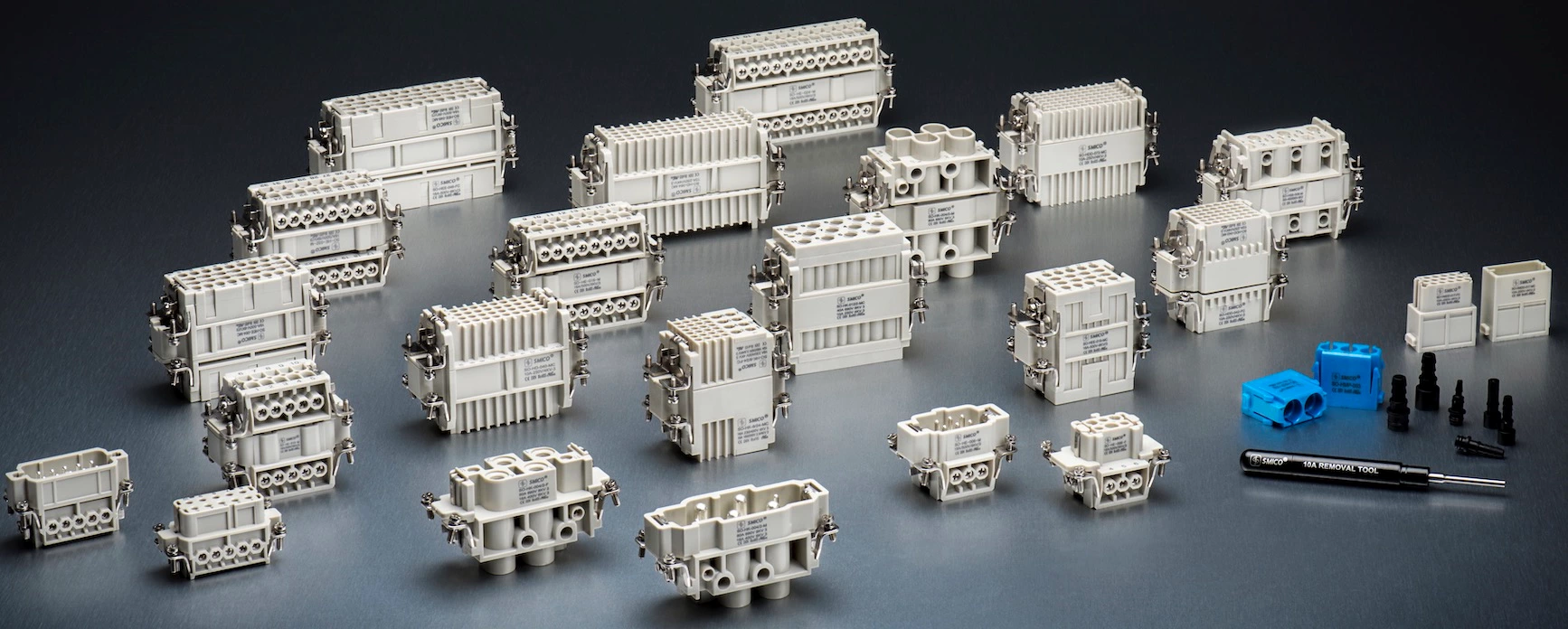

The heavy-duty connector can realize the transmission of power and signal in a single connector, which makes the wiring of automation equipment more reasonable and the engineering application can be carried out efficiently.

Heavy-duty connectors are mainly used in pitch control systems, nacelles (electrical control cabinets, slip rings, brakes, yaw systems, converter systems, fan communication systems, etc.) and tower systems to provide connecting components and solutions on wind turbines .

Heavy-duty connectors are used in inverters in the solar power generation industry, variable speed systems in the wind power generation industry, high and low voltage switch cabinets in the thermal power generation industry, vacuum circuit breakers in the transmission and distribution grid industry, power distribution cabinets in substations, intelligent Junction boxes in the power grid industry are widely used.

With its unique advantages, heavy-duty connectors are widely used in vacuum circuit breakers, which are based on the physical power grid, and are widely used in a new smart grid that integrates advanced sensing and measurement technology, communication technology, information technology, computer technology and control technology. , high-voltage switch cabinets, box-type substations and other occasions.

In rail transit technology, the modular design of components has been paid more and more attention due to the requirements of refined division of labor and convenient maintenance, and the flexibility and compactness of heavy-duty connectors are very well reflected in rail transit applications. , used in traction systems, air conditioning systems, access control systems, lighting systems, etc. of rail transit.

In the field of machinery manufacturing, due to the diversification of equipment and space requirements, in some occasions, in addition to the transmission of strong and weak electricity, it is also necessary to transmit media such as light and gas.

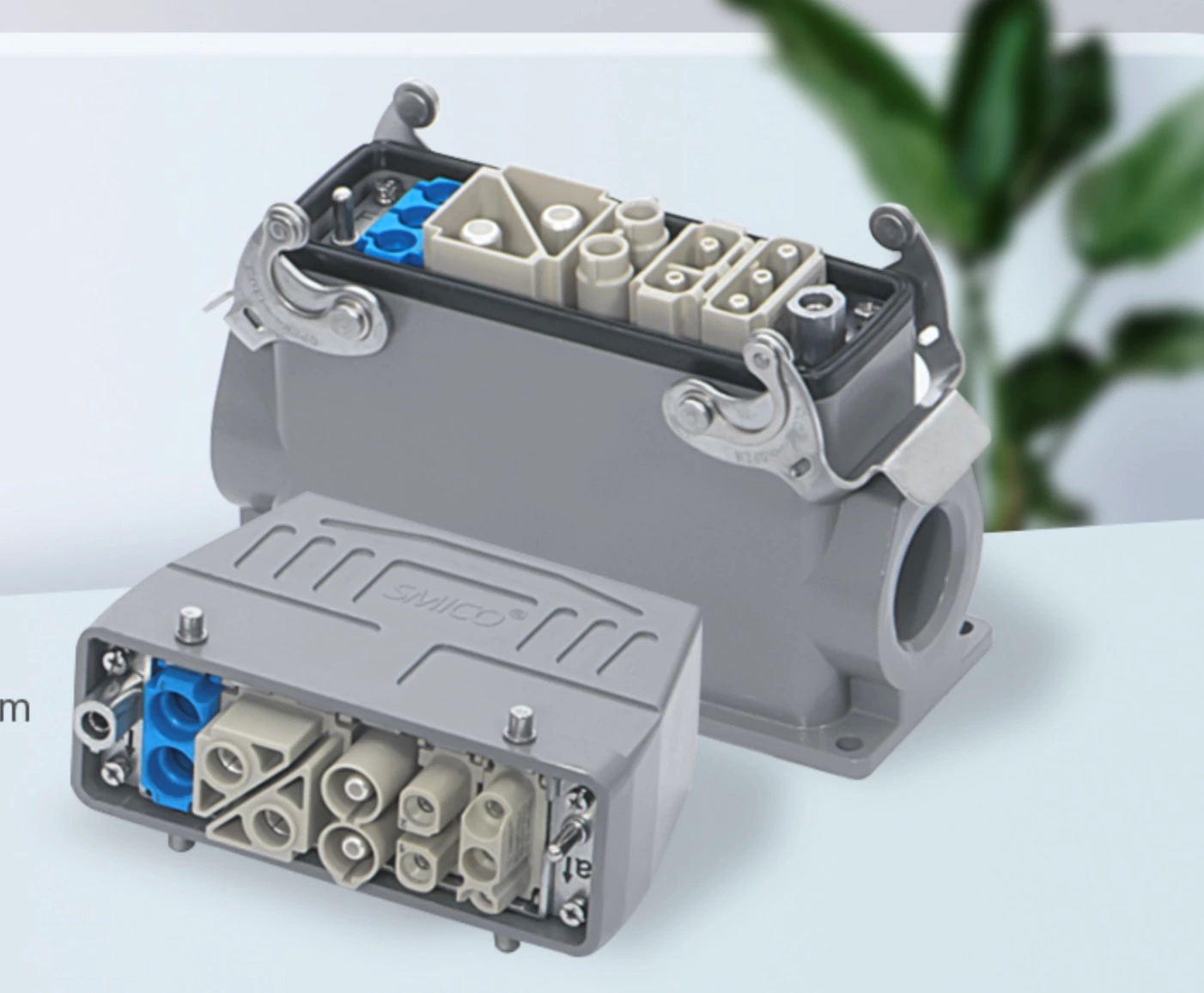

The types of heavy-duty connectors are flexible and can meet different applications of various equipment. If necessary, the connection of electrical and pneumatic circuits can be realized simultaneously in one connector.

The requirements for reliability, diversification, high-rise and high environment of the construction industry in the future, as well as the general trend of energy saving and environmental protection, will definitely drive the development of construction machinery. The advantages of heavy-duty connectors, such as multiple varieties, high current, and high protection, escort construction machinery.

The 4-pin, 16-pin, and 24-pin heavy-duty connectors are widely used in hot runner molds, temperature control boxes and some extrusion equipment.