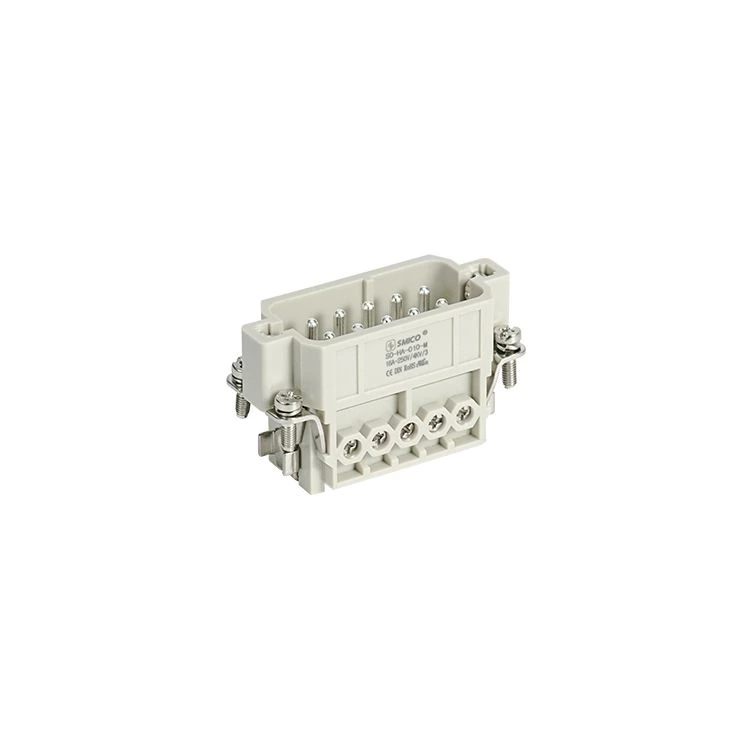

Heat Protection For Heavy-duty Connectors

With the arrival of hot summer, the temperature rises, which adds a high temperature problem to the working environment of Heavy Duty Connector. So what problems do we need to know and solve to avoid heat?

Here are a few examples: 1. The engine piston temperature is too high, which can easily lead to overheating and melting, resulting in cylinder sticking;

2. Rubber seals, triangular tapes, tires, etc. are overheated, which are prone to premature aging, performance degradation, and shortened service life;

3. The coils of electrical equipment such as starters, generators, and regulators are overheated and are easily burned and scrapped.

Therefore, in the working environment of heavy-duty connectors, production specifications should be met, including production processes, steps, and strict temperature and humidity control in the production environment, so that the performance of heavy-duty connectors can be maximized and the life can be maximized.