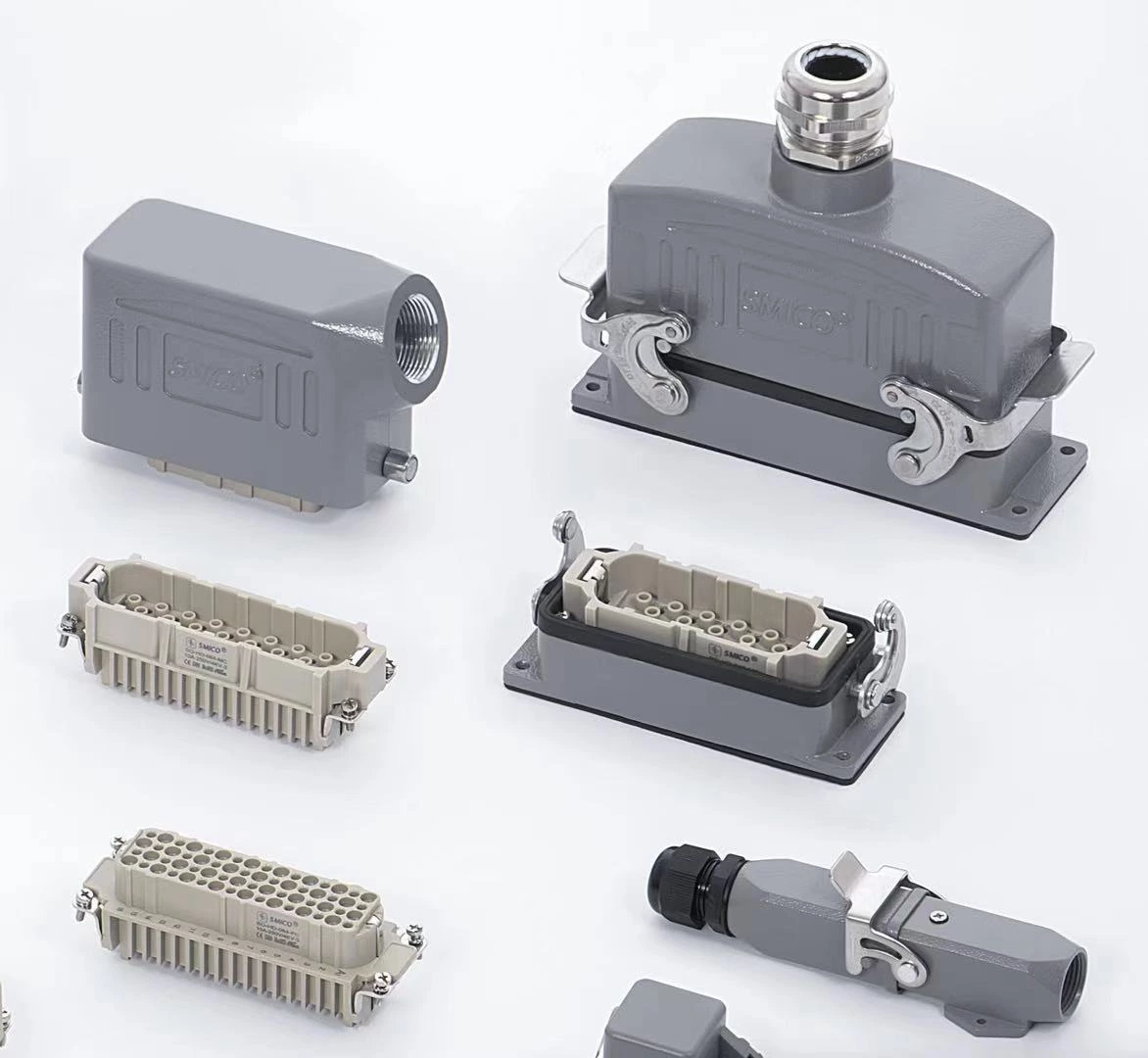

Connection mode of heavy-duty connector

Connection technology

The most common wiring technology can be integrated into the SMICO connector. Special ferrules and pins can be used to match specific wire wiring technology. The choice of the correct wiring technique mainly depends on the cable type, cable cross section, and the number and type of pins. In addition, various wiring types can also provide different advantages for different production conditions.

Crimp pin

Suitable for fast wiring, it is ideal for pre-assembly of large-volume connectors

Using suitable crimping tools, consistent crimp quality and excellent corrosion resistance can be achieved, almost comparable to cold welding

Due to the high pin density, very little space is required

Screw connection technology

Simple and intuitive operation

Can be installed on site without any special tools

Bolt wiring with wire protection, can also be used for stranded wires

HQ Lock

Perfectly combine the reliability and ease of operation of spring wiring technology with the minimum space requirements of crimping pins

Can be installed on site without any special tools

Can quickly connect stranded wires

Coaxial bolt connection method

Perfectly combines the ease of operation of screw wiring technology with the minimum space requirements of crimping pins

Can be installed on site without any special tools

Suitable for fine stranded wires with large cross-sections

Cage shrapnel wiring

Simple and convenient processing can be realized without any special tools

Suitable for solid wires and stranded wires from .14 to 2.5mm². As the conductor cross-section increases, the crimping force will be greater

Excellent functional safety: the wire connection is resistant to vibration/shock and has a consistent low pressure drop