Application fields and advantages of SMICO heavy-duty connectors

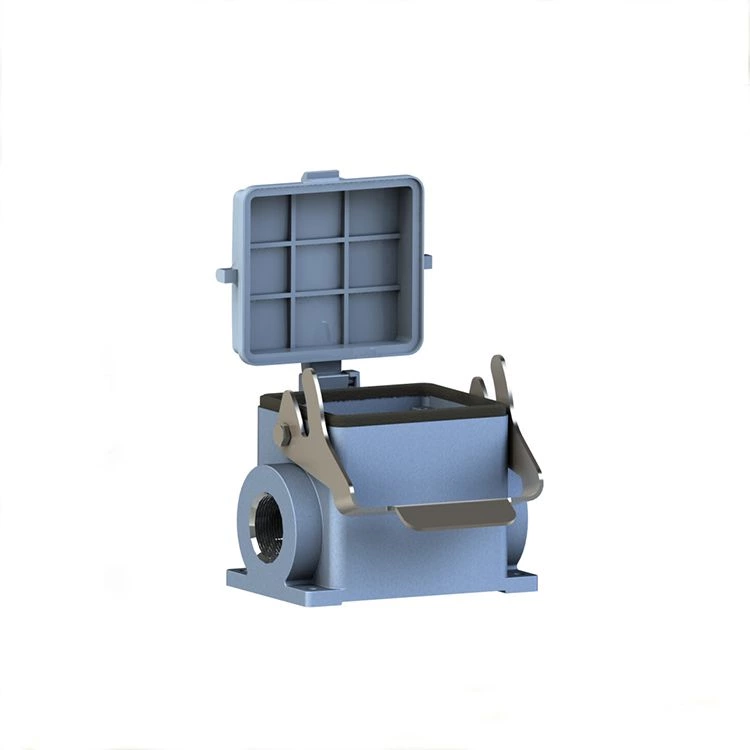

SMICO heavy-duty connectors are widely used in multiple industrial fields due to their high performance and adaptability, especially in complex environments and harsh working conditions. The following is a summary of its main application areas and related technical advantages:

1. Core application areas

Industrial automation and intelligent manufacturing

Heavy-duty connectors support modular design in industrial automation equipment, can be quickly plugged in and out, and can realize pre-installation of complex circuits, significantly reducing wiring errors and improving equipment installation efficiency. For example, in robots and automated production lines, its modular structure supports flexible expansion and saves 20%-30% of installation costs.

Power energy and power transmission and distribution systems

Applied to power plants, transmission lines, switching power supplies and other scenarios, it can carry high voltage and high current of more than 1000V to meet the long-term high load requirements of the power system. Its waterproof and anti-corrosion properties (protection level IP67) ensure the stable operation of outdoor power equipment.

Railway transportation and transportation equipment

In railway locomotives, subways and other systems, heavy-duty connectors adapt to extreme climates and vibration environments and are used for power transmission and signal control. For example, the electronic control management system of electric locomotives relies on its seismic resistance and durability to ensure safe operation.

Mechanical Manufacturing and Engineering Machinery

It is widely used in construction machinery, textile machinery, packaging and printing machinery and other fields. Its dustproof and waterproof design (IP67) and impact resistance enable it to maintain a stable connection under complex working conditions of construction machinery.

Medical Equipment and Aerospace

In the medical field, it is used for precise signal transmission in operating rooms and inspection equipment; in the aviation field, its high temperature resistance and high pressure difference make it suitable for aircraft communications and radar systems.

2. Technical advantages support application scenarios

High load and durability: support large current (above 1000V) and long-term use (lifespan of decades), suitable for high-intensity scenarios such as power and rail transit.

Protection performance: IP67 protection level, anti-smog, seismic design, suitable for outdoor and harsh industrial environments.

Modularity and flexibility: support mixed transmission of power and signals, and can expand multiple functional modules to meet the diversified needs of intelligent manufacturing and automation equipment.

Convenience of operation: The plug-in design simplifies installation and maintenance, reduces labor costs, and avoids the high risk of errors in hard wiring.

3. Applications in other industries

Petrochemical and tobacco machinery: Ensure the reliability of electrical connections in explosion-proof and corrosion-resistant environments.

Hot runners and robots: Achieve high-speed data transmission and safety protection, and improve the level of equipment intelligence.

Summary

Through modular design, high protection level and diversified transmission capabilities, CIMEC heavy-duty connectors have become key components of Industry 4.0 and smart manufacturing. Its application not only covers traditional manufacturing, but also extends to emerging fields such as smart grids and medical equipment, fully reflecting the industry adaptability driven by technology. For more detailed technical parameters or industry cases, please refer to CIMEC's official website and industry application report