Heavy Duty Rectangular Temperature Controller Connectors 24 pin

- Part:

- SO-HE-024-M

- Number of contacts:

- 24pin

- Rated current:

- 16A

- Rated voltage conductor:

- 500V

- Product Certification:

- UL CUL CE ROHS DMT IEC-61984

- Order No.:

- 09330242601

- Packaging Details:

- Standard Export Cartons

- Delivery Time:

- Within 7 Days

- Payment Terms:

- L/C, T/T, Western Union, Paypal

- Supply Ability:

- 100000 pcs per month

Heavy duty connector rectangular - Heavy Duty Rectangular Temperature Controller Connectors 24 pin - China Smico Electrical

Heavy Duty Rectangular Temperature Controller Connectors 24 pin 09330242601

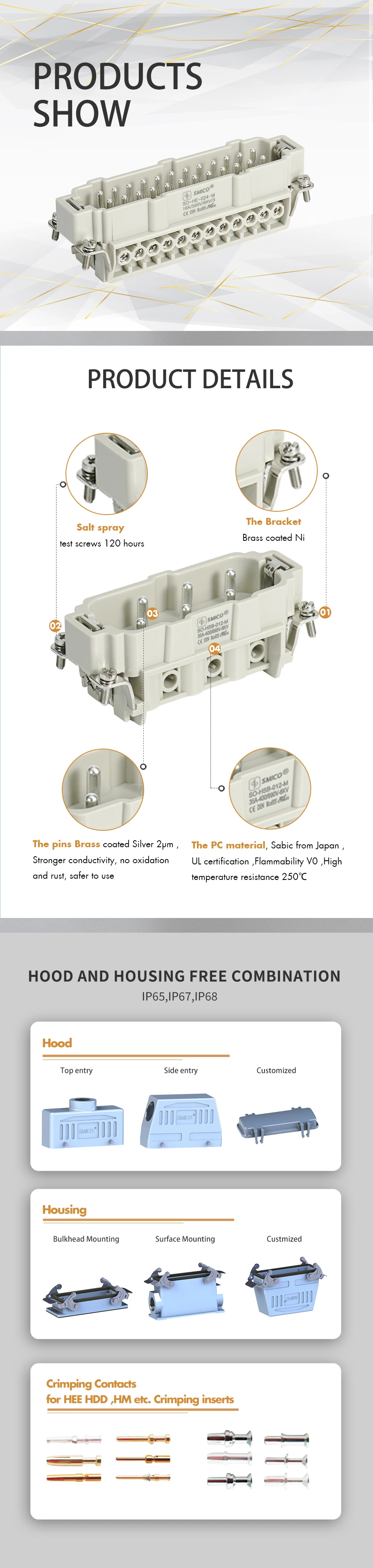

Heavy Duty Rectangular connectors for Temperature control box: The hot runner temperature control box includes the host, cables, connectors and wiring male and female sockets, etc.

24Poles+PE,16A,screw Male insert

| Inserts | Suitable Shell:24BHood/Housing |

| Number of contacts | 24 |

| Electrical data acc. to EN 61 984 | |

| ---Rated current | 16A |

| ---Rated voltage conductor | 500V |

| ---Rated impulse voltage | 6kV |

| ---Pollution degree | 3 |

| ---Pollution degree 2 also | 16A 400/690V 6kV 2 |

| Rated voltage acc. to UL/CSA | 600V |

| Insulation resistance | ≥1010Ω |

| Material | polycarbonate |

| Limiting temperatures | -40℃...+125℃ |

| Flammability acc. to UL 94 | V0 |

| Mechanical working life(mating cycles) | ≥500 |

| Contacts | |

| Material | copper alloy |

| Surface | hard-gold plated |

| hard-silver plated | |

| Contact resistance | ≤1mΩ |

| Screw terminal | |

| ---Wrie gauge | 0.14-2.5mm2 |

| ---AWG | 26-14 |

| ---Tightening/Test torque | 0.5N·m |

| ---Stripping length | 7.0mm |

SMICO heavy duty connector can match the following interchangeable.

The hood and housing for H24B .

| Suppier | Plug insert | Socket insert |

| SMICO | SO-HE-024-M | SO-HE-024-F |

| HARTING | 09330242601 | 09330242701 |

| ILME | CNEM 24 T | CNEF 24 T |

| TE | ||

| LAPP EPIC | 10.1960 | 10.1970 |

| PHOENIX | 1648296 | 1648306 |

| MOLEX | ||

| WEIDMULLER | HDC HE 24 MS | HDC HE 24 FS |

| WIELAND | 70.310.2402.0 | 70.300.2402.0 |

| AMPHENOL |

Applications

- Machinery

- Automation

- Robotics

- Rail

- Energy Distribution

- Renewable Energy

- Construction Machinery

- Professional Light and Sound

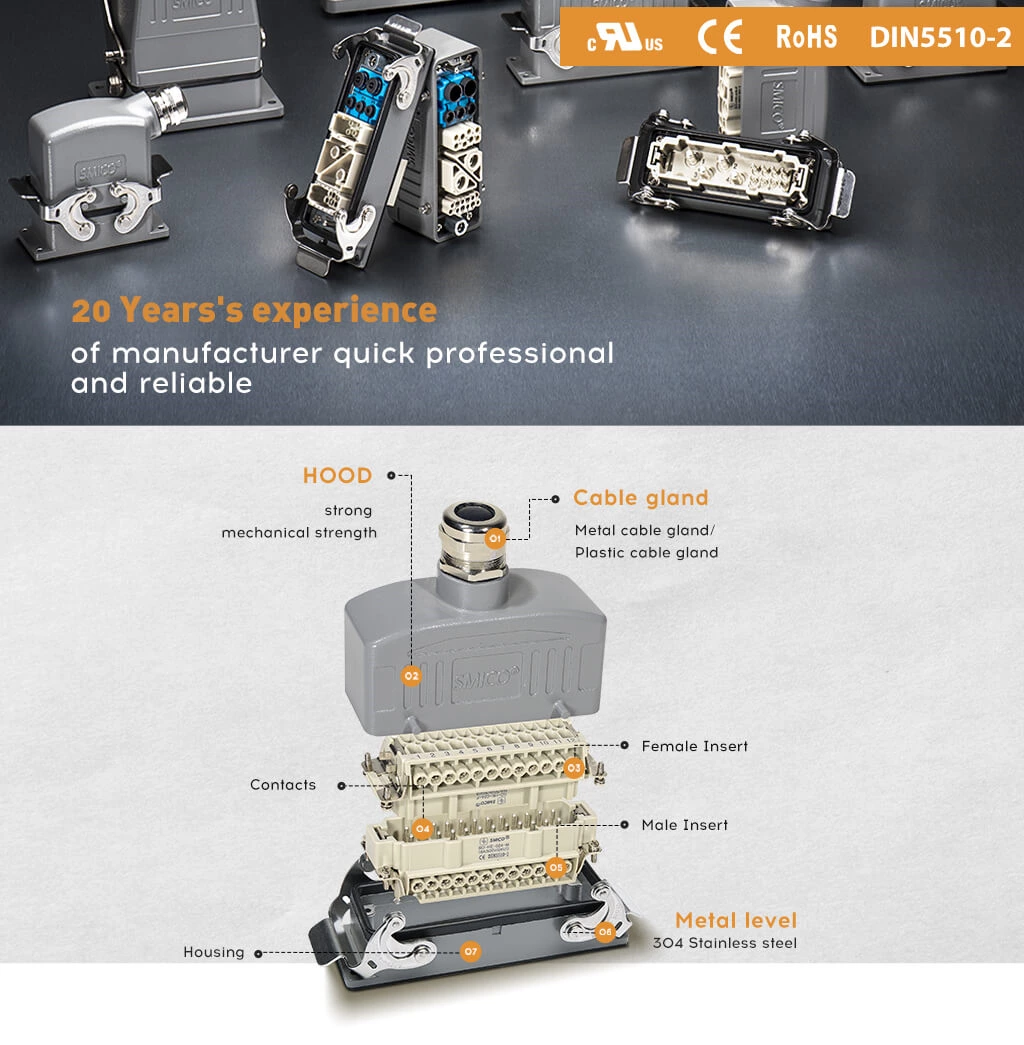

1. What is a heavy-duty connector

The international advancement of heavy-duty connectors in terms of structural design and material use makes the connectors outstanding in terms of electrical performance. The reliability of the electrical connection system is beyond the reach of traditional connection methods. Compared with the traditional connection method, the use of heavy-duty connectors has the advantages of pre-installation, pre-wiring, preventing mis-insertion, and improving work efficiency.

2. The principle of heavy-duty connector

a. Realize pre-installation, pre-installation of a large number of and complex circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

b. The heavy-duty connector provides a highly integrated connection, and the rich combination methods maximize the effective utilization of the equipment space.

v. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block of the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

d. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system in the harsh environment. Provide effective protection in harsh environments such as sand, rain, cold, ice and snow, and oil pollution.

3. The role of heavy-duty connector

This new interface is generally considered an "industrial connector", and its applications are not limited to manufacturing. This connector is designed to withstand the harshest industrial environments. Traditional connected devices provide users with a service guarantee for several years in a typical office environment. However, exposing the same copper cable or optical fiber connector to extreme conditions will reduce its performance and reliability, and end users must pay high maintenance costs to troubleshoot and replace parts. A new connector, which is specifically designed to build a sturdy Ethernet connection in harsh environments, which is tougher, stronger, and more resistant than previous connectors.

Heavy-duty connectors are widely used in construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, robots, rail transit, hot runners, electricity, automation and other equipment that require electrical and signal connections