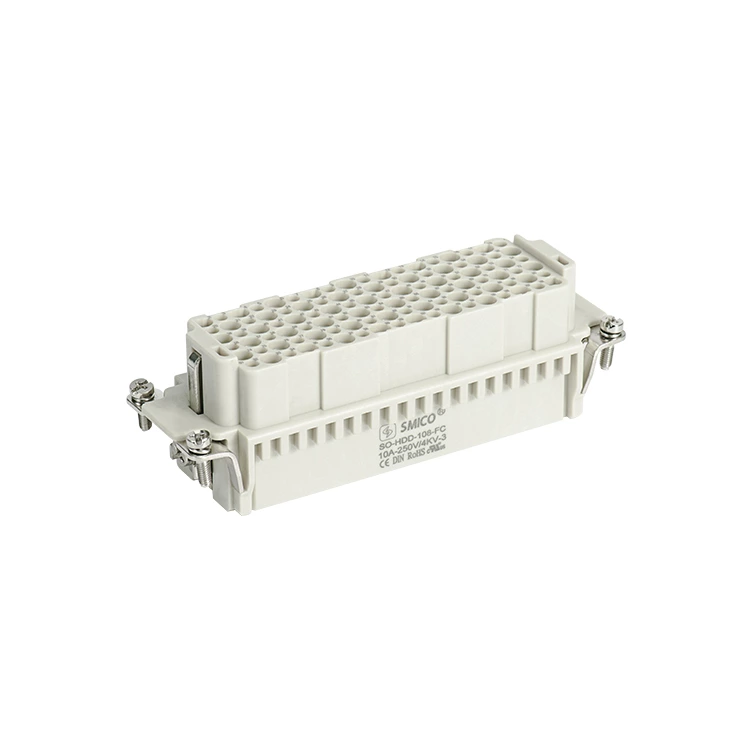

Industrial plug and socket 216 pins multi pole connectors

- Part:

- SO-HDD-216-MC

- Number of contacts:

- 216 Pins

- Rated current:

- 10A

- Rated voltage conductor:

- 250V

- Product Certification:

- UL CUL CE ROHS DMT

- Order No.:

- 09161083011

- Packaging Details:

- Standard Export Cartons

- Delivery Time:

- Within 7 Days

- Payment Terms:

- L/C, T/T, Western Union, Paypal

- Supply Ability:

- 100000 pcs per month

Industrial plug and socket 216 pins multi pole connectors

Industrial plug and socket 216 pins multi pole connectors more wires collected in one connector and each to install , quickly to find the wire that you want to change

216 Poles + PE, 10 A Male Crimping Terminal :

| Inserts | Suitable Shell:48BHood/Housing |

| Number of contacts | 216 |

| Electrical data acc. to EN 61 984 | |

| ---Rated current | 10A |

| ---Rated voltage conductor | 250V |

| ---Rated impulse voltage | 4kV |

| ---Pollution degree | 3 |

| ---Pollution degree 2 also | 10A 230/400V 4kV 2 |

| ---Rated voltage acc. to UL/CSA | 600V |

| Insulation resistance | ≥1010Ω |

| Material | polycarbonate |

| Limiting temperatures | -40℃...+125℃ |

| Flammability acc. to UL 94 | V0 |

| Mechanical working life(mating cycles) | ≥500 |

| Contacts | |

| Material | copper alloy |

| Surface | hard-gold plated |

| hard-silver plated | |

| Contact resistance | ≤3mΩ |

| Crimp terminal | |

| ---Wrie gauge | 0.14-2.5mm² |

| ---AWG | 26-14 |

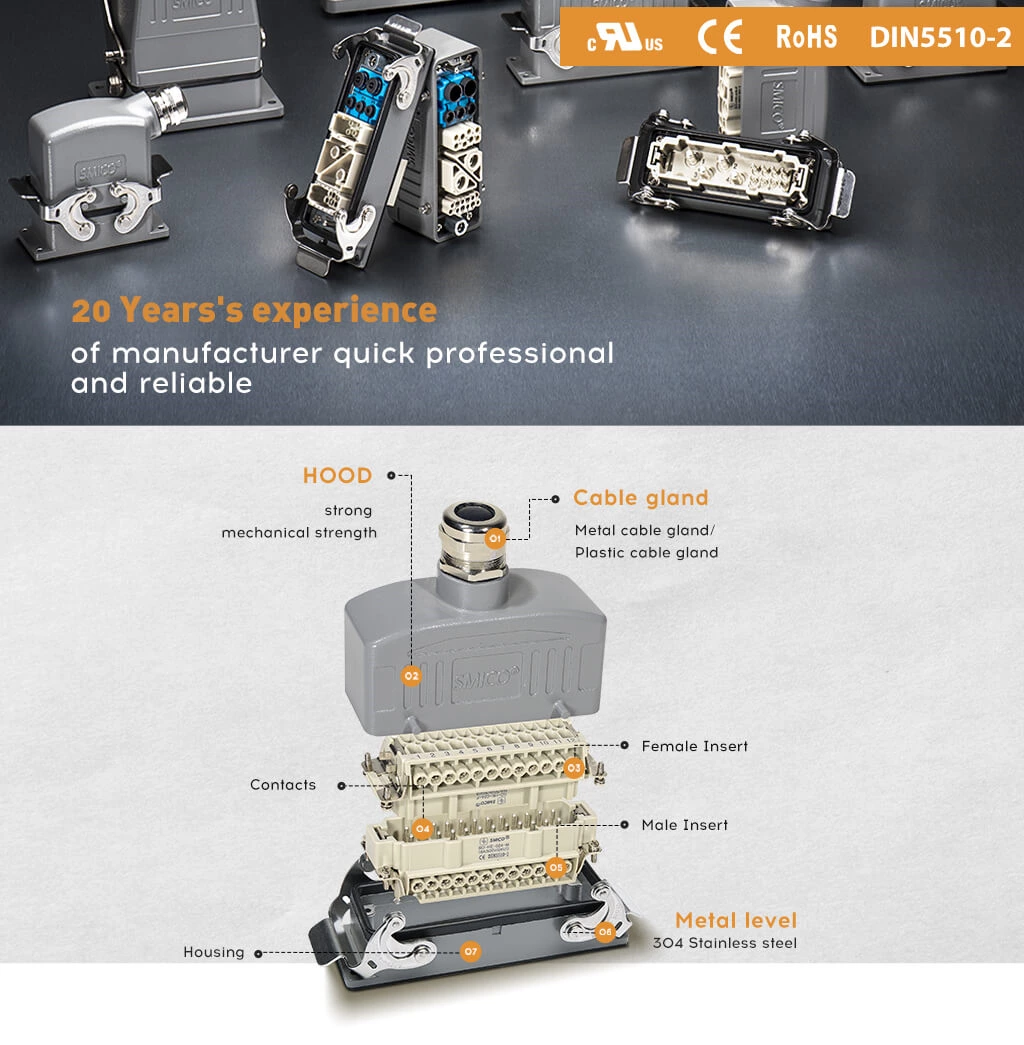

SMICO heavy duty connector can match the following interchangeable.

The hood and housing for H48B .

| Suppier | Plug insert | Socket insert |

| SMICO | SO-HDD-216-MC | SO-HDD-216FC |

| H | 09161083001 09161083011 | 09161083101 09161083111 |

| ILME | CDDM 108 CDDM 108 N | CDDF 108 CDDF 108 N |

| TE | ||

| LAPP EPIC | 11.2853 11.2855 | 11.2863 11.2865 |

| PHOENIX | 1584114 1584127 | 1584130 1584143 |

| MOLEX | ||

| WEIDMULLER | HDC HDD 108 MC HDC HDD 108 MC 109-216 | HDC HDD 108 FC HDC HDD 108 FC 109-216 |

| WIELAND | 73.810.0853.0 | 73.800.0853.0 |

| AMPHENOL |

Specializing in machinery, bid farewell to "Farewell"-SMICO releases new compact heavy-duty connectors

Indeed, heavy-duty connectors, which originated from the custom-developed train carriage connection requirements in the 1950s, have been widely used in industry due to their high reliability and ruggedness. But today, the application environment of heavy-duty connectors has changed. In the connection scenarios of most mechanical equipment, the design of traditional heavy-duty connectors has been too wasteful.

"Fanxue"? Or is it overdesign?

In the early mechanical equipment market, HDC plug-in requirements and applications also borrowed from train HDC products, and they are generally used today.

But for a long time, the matching degree and cost performance of many HDC products in the machinery market have not been satisfactory. This is also a problem caused by industry gaps. Take the equipment in the rail transit industry as an example. Their application environment is much higher than that of mechanical equipment. The parameters that many heavy-duty connectors meet greatly exceed the requirements of mechanical equipment, such as:

●Expensive turning round pins equipped to meet the high vibration requirements of the track;

●The long-term frequent replacement of carriages or train equipment requires a high mating life of 500 times;

●Wide temperature range, long-term salt spray corrosion resistance and high IP protection required by the harsh outdoor environment of the train;

●Impact resistance required to deal with accidental impact of rocks during track operation...