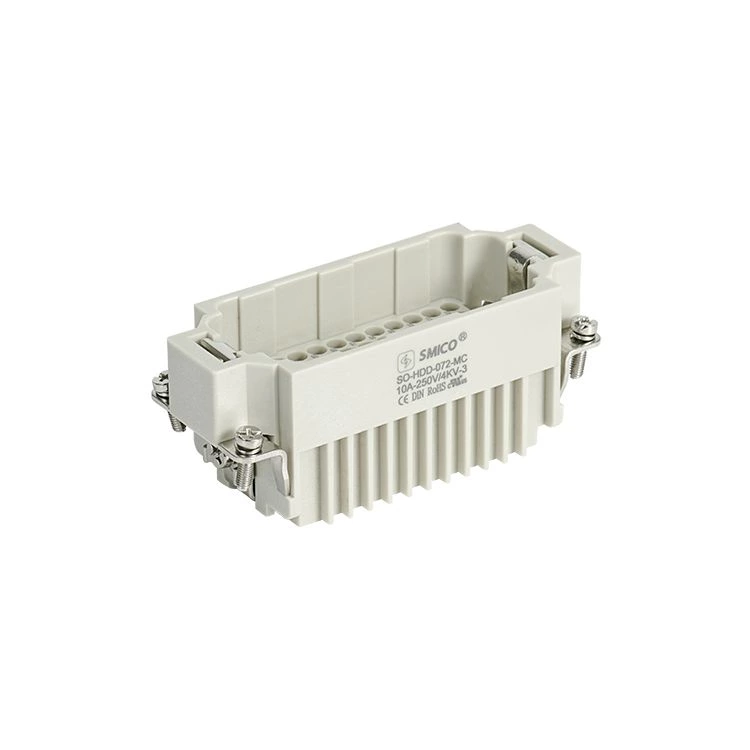

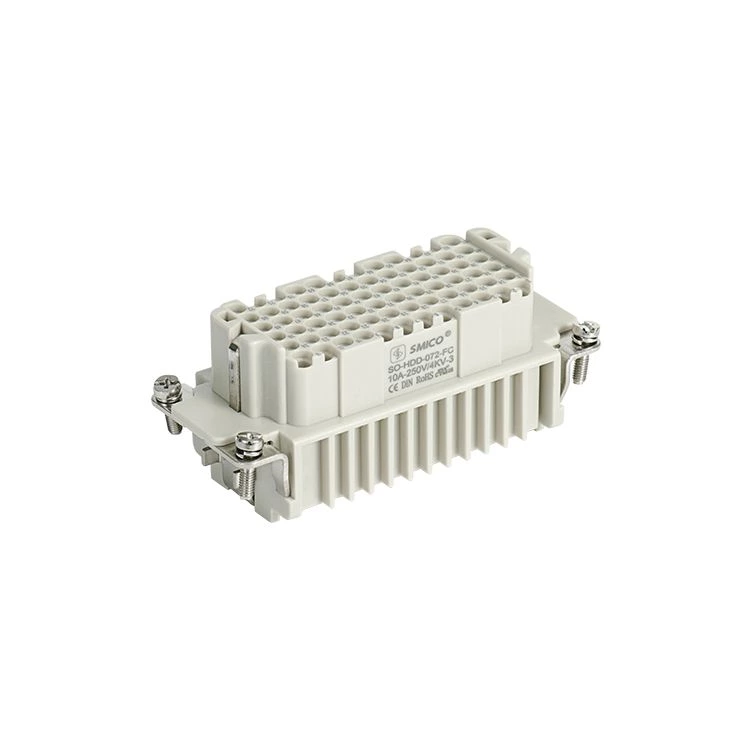

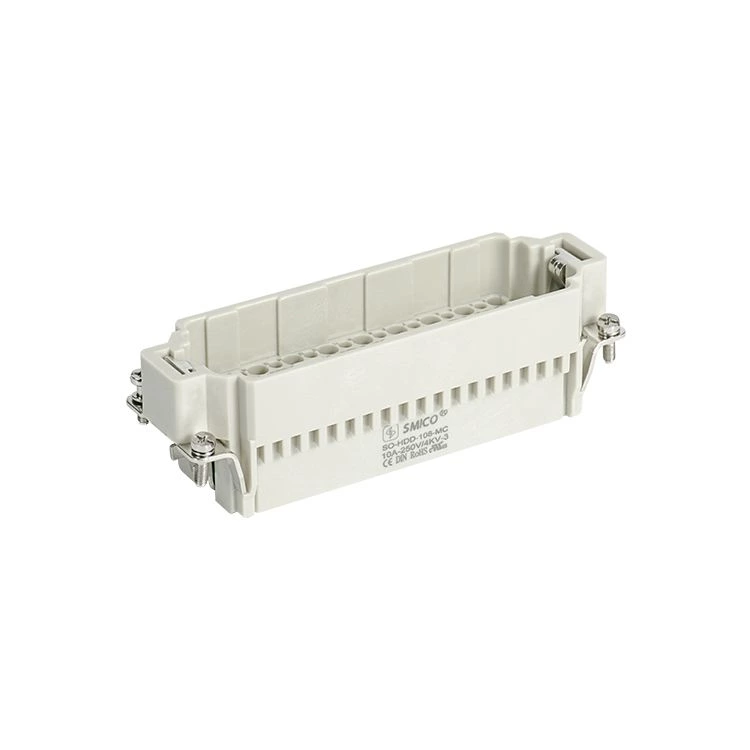

72 pins HDD heavy duty connector used for sweeping machine

- Part:

- SO-HDD-072-MC

- Number of contacts:

- 72 pins

- Rated current:

- 10A

- Rated voltage conductor:

- 250 V

- Product Certification:

- UL CUL CE ROHS DMT

- Order No.:

- 09160723001

- Packaging Details:

- Standard Export Cartons

- Delivery Time:

- Within 7 Days

- Payment Terms:

- L/C, T/T, Western Union, Paypal

- Supply Ability:

- 100000 pcs per month

72 pins HDD heavy duty connector used for sweeping machine

72 pins HDD heavy duty connector used for sweeping machine , with crimp power terminal , used for Road construction projects .

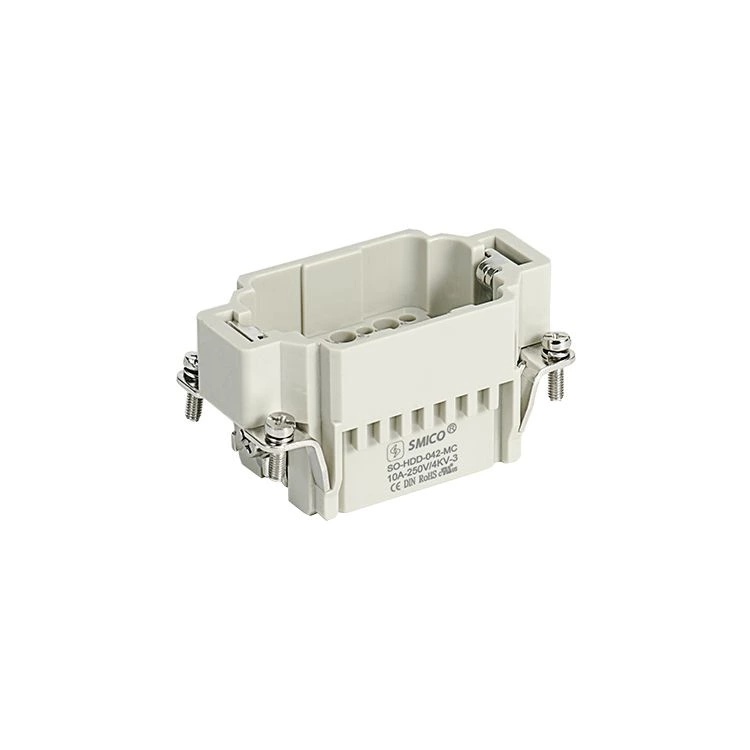

72Poles + PE, 10 A Male Crimping Terminal :

| Inserts | Suitable Shell:16BHood/Housing |

| Number of contacts | 72 |

| Electrical data acc. to EN 61 984 | |

| ---Rated current | 10A |

| ---Rated voltage conductor | 250V |

| ---Rated impulse voltage | 4kV |

| ---Pollution degree | 3 |

| ---Pollution degree 2 also | 10A 230/400V 4kV 2 |

| Rated voltage acc. to UL/CSA | 600V |

| Insulation resistance | ≥1010Ω |

| Material | polycarbonate |

| Limiting temperatures | -40℃...+125℃ |

| Flammability acc. to UL 94 | V0 |

| Mechanical working life(mating cycles) | ≥500 |

| Contacts | |

| Material | copper alloy |

| Surface | hard-gold plated |

| hard-silver plated | |

| Contact resistance | ≤3mΩ |

| Crimp terminal | |

| ---Wrie gauge | 0.14-2.5mm² |

| ---AWG | 26-14 |

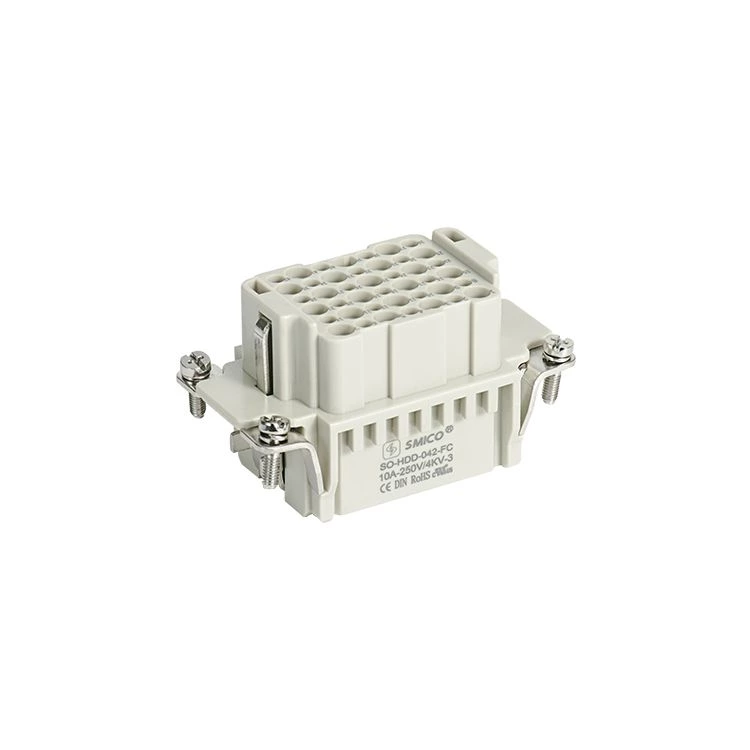

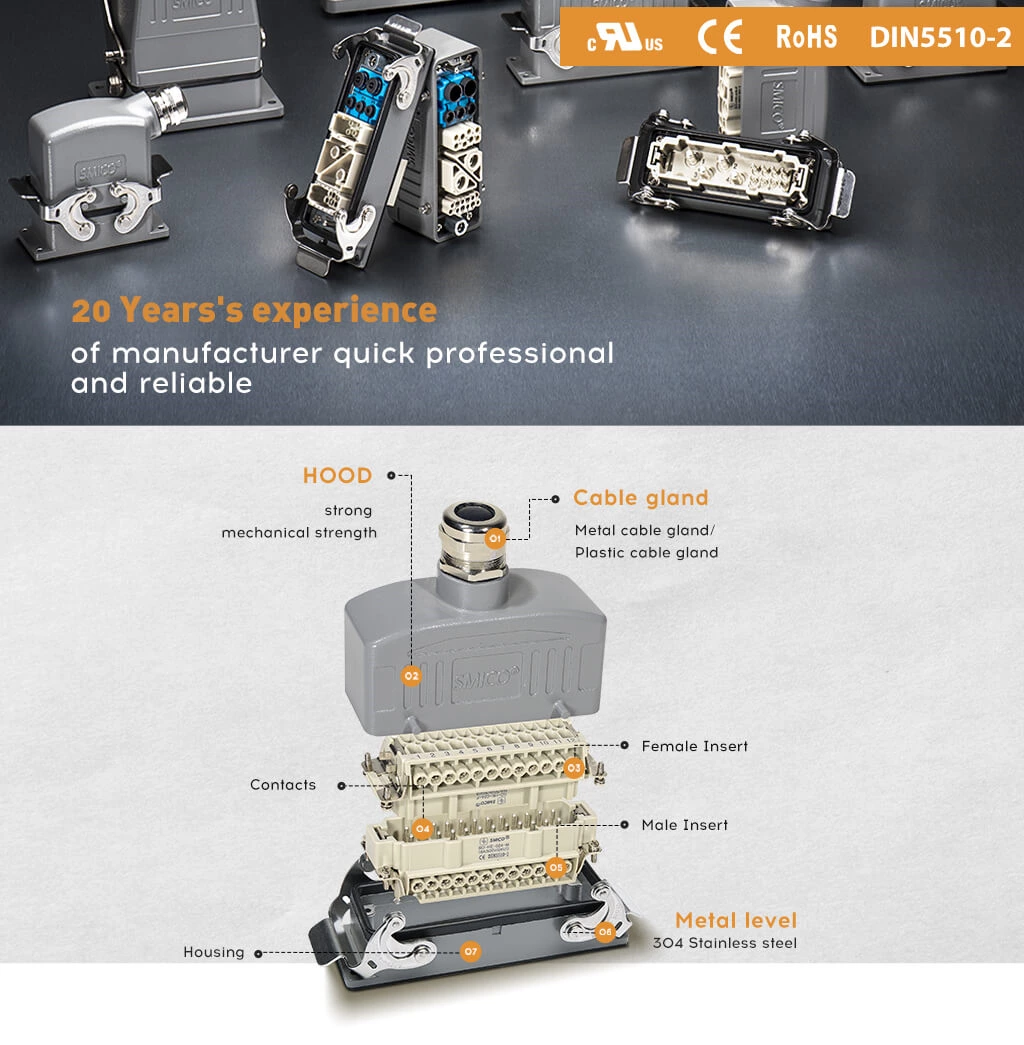

SMICO heavy duty connector can match the following interchangeable.

The hood and housing for H16B .

| Suppier | Plug insert | Socket insert |

| SMICO | SO-HDD-072-MC | SO-HDD-072-FC |

| H | 09160723001 | 09160723101 |

| ILME | CDDM 72 | CDDF 72 |

| TE | ||

| LAPP EPIC | 11.2852 | 11.2862 |

| PHOENIX | 1584075 | 1584091 |

| MOLEX | ||

| WEIDMULLER | HDC HDD 72 MC | HDC HDD 72 FC |

| WIELAND | 73.810.4253.0 | 73.800.7253.0 |

| AMPHENOL |

The international advancement of heavy-duty connectors in terms of structural design and material use makes the connectors outstanding in terms of electrical performance. The reliability of the electrical connection system is beyond the reach of traditional connection methods.

1. Realize pre-installation, pre-installation of a large number of and complex circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

2. The heavy-duty connector provides a highly integrated connection, and the rich combination methods maximize the effective utilization of the equipment space.

3. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block of the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

4. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system under the harsh environment. Provide effective protection in harsh environments such as sand, rain, cold, ice and snow, and oil pollution.

Heavy-duty connectors are specially designed and applied to meet the requirements of harsh environmental conditions. The main application areas are industrial automation, equipment manufacturing and industrial system buildings, as well as information and control technology.

Its shell protects the instrument from rain, ice and dust. Compared with the traditional connection method, the use can save 20-30% of the installation cost of the machining center; it increases the production efficiency and reduces the error rate of the wiring.

Such products are widely used in machinery, industrial systems and transmission equipment. With the in-depth development of industrial automation, more innovations have appeared in mechanical products. For example, many products have been modularized and expanded in accordance with the needs of the application. The use of heavy-duty aviation plug connectors including pneumatic modules and high-current modules not only realizes the barrier-free and fast connection between modular devices, but also ensures the transmission of signals and power supply.

For machinery and equipment manufacturers, it can save installation time, secure and reliable connections, and reduce overall production costs. For terminal users, they can freely install and operate equipment without any professional guidance. It also becomes easy to maintain. This not only increases the effectiveness and practicability of the mechanical equipment, but also reduces the parking time and the equipment maintenance time. The efficiency has been effectively improved. Meet the needs of customers.