Rectangle socket insert 128 pins for heavy duty connectors

- Part:

- SO-HD-128-FC

- Number of contacts:

- 128

- Rated current:

- 10A

- Rated voltage conductor:

- 250V

- Product Certification:

- UL CUL CE ROHS DMT

- Order No.:

- 09210643101

- Packaging Details:

- Standard Export Cartons

- Delivery Time:

- Within 7 Days

- Payment Terms:

- L/C, T/T, Western Union, Paypal

- Supply Ability:

- 100000 pcs per month

Rectangle socket insert 128 pins for heavy duty connectors

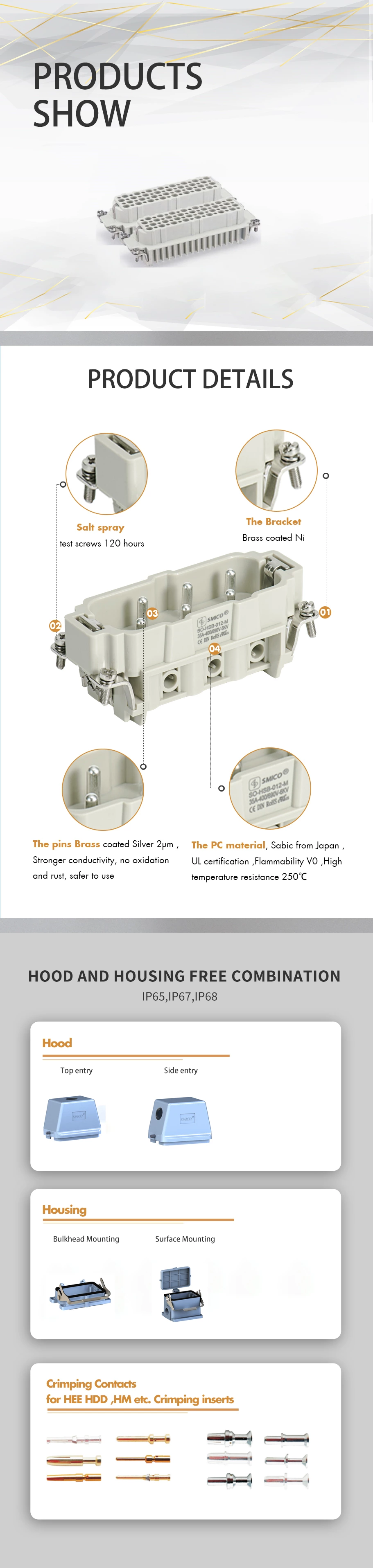

Rectangle socket insert 128 pins for heavy duty connectors connect the wire at or less 10A ,250V . for the machine or equipment that used .

128Poles + PE, 10A Female Crimping terminal :

| Inserts | Suitable Shell:48BHood/Housing |

| Number of contacts | 128 |

| Electrical data acc. to EN 61 984 | |

| ---Rated current | 10A |

| ---Rated voltage conductor | 250V |

| ---Rated impulse voltage | 4kV |

| ---Pollution degree | 3 |

| ---Pollution degree 2 also | 10A 230/400V 4kV 2 |

| ---Rated voltage acc. to UL/CSA | 600V |

| ---Rated voltage for wrap terminal acc. to CSA | 2A 30V |

| Insulation resistance | ≥1010Ω |

| Material | polycarbonate |

| Limiting temperatures | -40℃...+125℃ |

| Flammability acc. to UL 94 | V0 |

| Mechanical working life(mating cycles) | ≥500 |

| Contacts | |

| Material | copper alloy |

| Surface | hard-gold plated |

| hard-silver plated | |

| Contact resistance | ≤3mΩ |

| Crimp terminal | |

| ---Wrie gauge | 0.14-2.5mm² |

| ---AWG | 26-14 |

SMICO heavy duty connector can match the following interchangeable.

The hood and housing for H48B .

| Suppier | Plug insert | Socket insert |

| SMICO | SO-HD-064-MC | SO-064-FC |

| H | 09210643001 | 09210643101 |

| ILME | CDM 64 | CDF 64 |

| TE | ||

| LAPP EPIC | 11.2720 | 11.2730 |

| PHOENIX | 1584431 | 1584444 |

| MOLEX | ||

| WEIDMULLER | HDC HD 64 MC | HDC HD 64 FC |

| WIELAND | 73.700.6458.0 | 73.710.6458.0 |

| AMPHENOL |

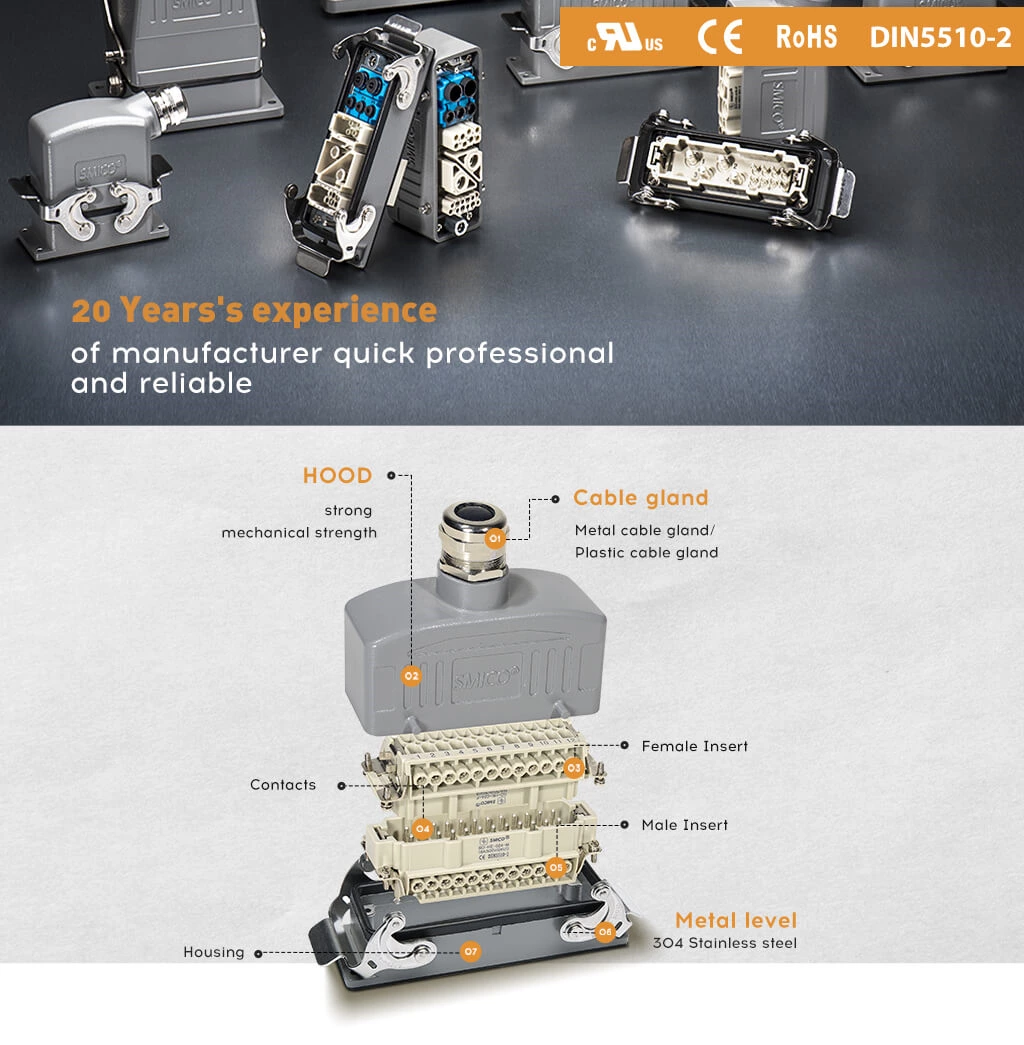

Heavy-duty connector purchase steps

Connectors are the most widely used electronic equipment in the industry, serving various "connection" tasks. But in some special harsh industrial environments such as dust, humidity, and mechanical stress, we need stronger, more durable, and more resistant connectors to connect the "interfaces" of wires and equipment. At this time, you need the "special forces" in the connector-the heavy-duty connector.

So here comes the question:

Generally, everyone will pick a connector, but how to choose a heavy-duty connector?

The first step is to determine the connection method of the connector.

The connection methods of heavy-duty connectors include screws, shrapnel, in-line, cold press, and coaxial screws.

The second step is to determine the number of loops, voltage and current.

The third step is to determine the cable connector.

Step 4, confirm the shell type.

The sturdy housing helps the connector to withstand frost and vibration.

Optional Tips: Heavy-duty connectors with different protective shells, dimensions, and cable entry methods are all different.